Déc . 19, 2024 16:59 Back to list

galvanized welded wire mesh iso factories

The Importance of Galvanized Welded Wire Mesh in Industrial Applications

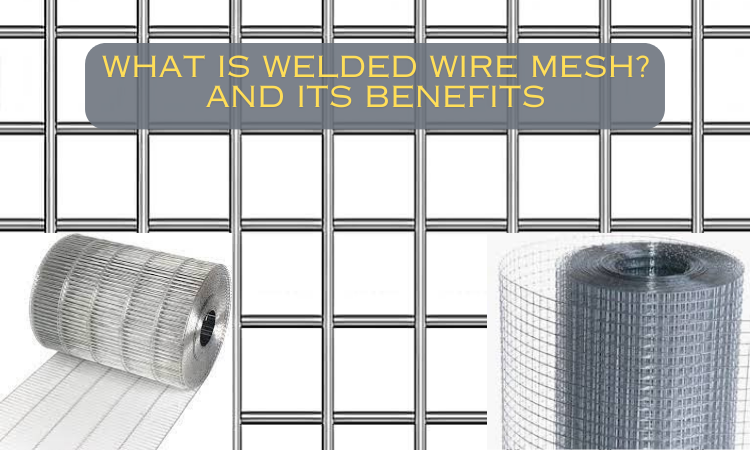

In the realm of industrial manufacturing, galvanized welded wire mesh has emerged as a crucial material, known for its durability and versatility. This type of wire mesh is made by welding together steel wires and then treating the welded product with zinc to prevent corrosion. The result is a robust and resilient mesh that serves various applications across industries, from construction to agriculture.

The Manufacturing Process

The production of galvanized welded wire mesh typically involves several key steps. First, high-quality steel wires are drawn to specific diameters and cut to predetermined lengths. Next, these wires are welded at intersection points using high-temperature processes, creating a grid-like structure. After welding, the entire mesh is subjected to galvanization—a process that involves coating the mesh with zinc to protect it against rust and degradation.

The galvanization process can be done in two primary ways hot-dip galvanizing and electro-galvanizing. Hot-dip galvanizing involves submerging the welded mesh in molten zinc, which allows for a thicker and more durable coating. In contrast, electro-galvanizing uses electrical currents to facilitate the deposition of zinc on the mesh. While this method offers a smoother finish, it generally results in a thinner coating. Manufacturers often choose between these methods based on the intended use of the wire mesh and environmental factors.

Key Benefits of Galvanized Welded Wire Mesh

1. Corrosion Resistance The zinc coating provides a protective barrier against environmental elements, making galvanized welded wire mesh ideal for outdoor applications. This feature significantly extends its lifespan, which is critical in sectors such as agriculture, construction, and fencing.

2. Strength and Durability The welding process results in a strong grid structure that can withstand significant forces and pressures. This strength makes it suitable for heavy-duty applications, including animal enclosures, industrial fencing, and even in supporting other construction materials.

galvanized welded wire mesh iso factories

3. Versatility Galvanized welded wire mesh can be used for various applications, including but not limited to

- Construction Used as reinforcement in concrete structures to enhance strength and rigidity. - Fencing Commonly employed for enclosing industrial areas and livestock pens due to its security and visibility. - Agriculture Ideal for creating protective barriers around crops and as cages for poultry and other animals.

4. Cost-Effectiveness Despite the initial investment in quality galvanized welded wire mesh, the long-term savings associated with reduced maintenance and replacement costs make it a cost-effective solution. The durability and performance of the mesh often outweigh the upfront costs.

Industries Utilizing Galvanized Welded Wire Mesh

Numerous industries benefit from the use of galvanized welded wire mesh. In construction, it plays a vital role in providing structural integrity to buildings and infrastructure projects. In agriculture, it serves as a reliable solution for fencing, livestock enclosures, and even as garden trellises. The automotive and aerospace industries also utilize this wire mesh for various applications, requiring high strength and lightweight materials.

Final Thoughts

As the demand for reliable and durable materials continues to grow, galvanized welded wire mesh stands out as a preferred choice across multiple sectors. Its unique combination of strength, corrosion resistance, and versatility ensures that it meets the rigorous requirements of today’s industrial applications. With advancements in manufacturing processes and continued innovation, the future of galvanized welded wire mesh looks promising, making it an essential component in modern construction and agriculture.

Understanding the fundamental aspects of this material can help industries optimize their usage, ensuring enhanced performance and longevity. Looking ahead, galvanized welded wire mesh is likely to play an even more significant role in sustainable and resilient construction practices, aligning perfectly with the goals of modern engineering and environmental stewardship.

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025