Jan . 02, 2025 13:58 Back to list

concrete steel bar welded mesh manufacturer

The Role of Concrete, Steel Bars, and Welded Mesh in Modern Construction

Concrete has long been recognized as one of the most ubiquitous building materials in the construction industry. Its versatility, durability, and cost-effectiveness make it an ideal choice for a wide range of applications, from residential buildings and commercial structures to infrastructure projects like bridges and roads. However, the strength of concrete itself can be significantly enhanced when combined with steel bars and welded mesh.

The Importance of Steel Reinforcement

Concrete is inherently strong under compression but weak under tension. This is where steel reinforcement comes into play. By incorporating steel bars (commonly known as rebar) into the concrete, builders can increase the tensile strength of the structure. The interplay between the concrete and the steel creates a composite material that can endure various stresses, ensuring the integrity and longevity of a building.

Steel bars come in various grades, diameters, and lengths, allowing engineers to design structures that meet specific requirements. Rebar is typically made from carbon steel, and its surface is often ribbed to improve adhesion with concrete. This bonding is crucial, as it allows the steel to effectively carry tensile loads and helps prevent cracking and structural failure in concrete members.

The Benefits of Welded Mesh

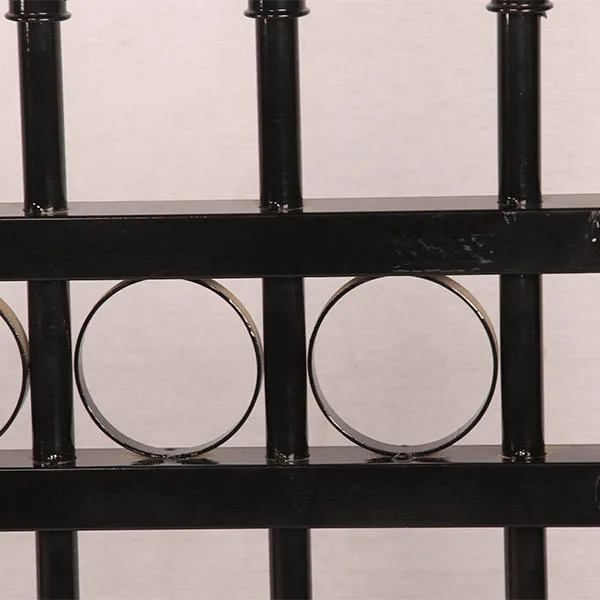

Welded wire mesh is another essential component in reinforced concrete construction. It consists of a grid of steel wires welded together at their intersections. This ready-made mesh is used in various applications, including floors, walls, and precast concrete products. One of the primary benefits of welded mesh is its ability to distribute loads more evenly across a surface. This is particularly useful in situations where large areas need reinforcement, such as slabs-on-grade and pavement.

Moreover, welded mesh offers significant time-saving advantages during construction. Instead of placing individual bars, workers can lay down entire sheets of mesh, reducing labor costs and speeding up the installation process. The strong interconnections between the wires in the mesh contribute to the overall structural integrity of the concrete, making it less prone to cracking and deformation.

concrete steel bar welded mesh manufacturer

Choosing the Right Manufacturer

When it comes to selecting a manufacturer for concrete, steel bars, and welded mesh, it is essential to consider several factors. Quality and compliance with industry standards should be top priorities. Manufacturers should adhere to guidelines set forth by organizations such as the American Concrete Institute (ACI) and ASTM International to ensure their products meet necessary safety and performance criteria.

Additionally, a reputable manufacturer will offer a range of products to cater to different construction needs. Whether it’s standard rebar, custom sizes, or specific grades of steel, having options allows professionals to tailor solutions to their projects. It’s also beneficial to choose a manufacturer that provides excellent customer service and technical support, ensuring that any questions or challenges encountered during implementation can be swiftly addressed.

The Environmental Impact

In recent years, the construction industry has been increasingly focused on sustainability. The combination of concrete, steel bars, and welded mesh is no exception. Many manufacturers are implementing eco-friendly practices, including the use of recycled materials in their steel production and the development of low-carbon concrete alternatives. By prioritizing sustainable practices, manufacturers can help reduce the industry's carbon footprint and contribute to greener building solutions.

Conclusion

In summary, concrete, steel bars, and welded mesh play crucial roles in modern construction, providing the strength, durability, and resilience needed for a variety of applications. As construction techniques advance and the demand for sustainable solutions grows, the relationship between these materials will continue to evolve. Selecting a reliable manufacturer is essential for ensuring high-quality materials that adhere to industry standards and meet the specific needs of each project. By doing so, builders can create safe, durable, and environmentally responsible structures that stand the test of time.

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025