آگوست . 16, 2024 18:05 Back to list

Top Suppliers of Reinforced Steel Mesh for Construction Needs

Understanding Reinforced Steel Mesh Manufacturers

When it comes to construction, the strength and durability of structures are paramount. One of the key components that contribute to this strength is reinforced steel mesh. This article delves into the significance of reinforced steel mesh, the manufacturing process, and what to consider when selecting a manufacturer.

What is Reinforced Steel Mesh?

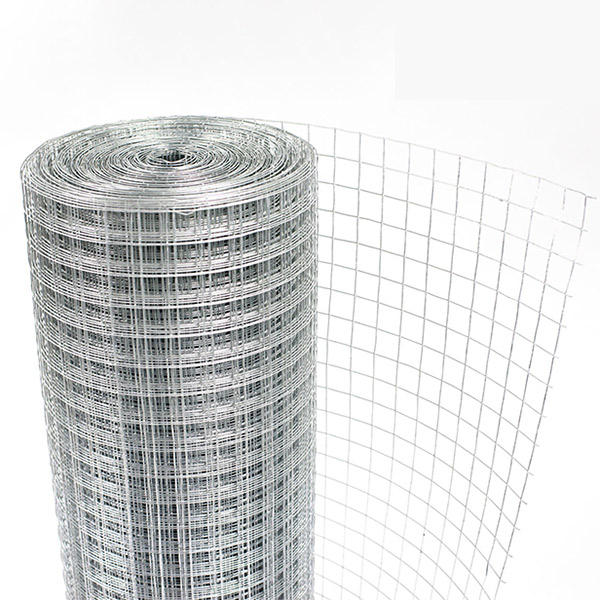

Reinforced steel mesh, commonly referred to as rebar mesh, consists of a grid of steel bars or wires. It is utilized primarily to enhance the tensile strength of concrete, which is naturally strong in compression but weak in tension. By embedding steel mesh in concrete, we can ensure that the final structure can withstand various stresses, thereby increasing its lifespan and reliability.

The Importance of Quality

The quality of reinforced steel mesh is crucial. Poorly manufactured mesh can lead to structural failures, resulting in costly repairs and safety hazards. Therefore, choosing the right manufacturer is essential. High-quality steel mesh is characterized by excellent weld integrity, uniform spacing, and adherence to international standards. Always verify that the manufacturer complies with industry norms such as ASTM or ISO to ensure you receive a product that meets safety and quality standards.

Manufacturing Process of Reinforced Steel Mesh

The manufacturing process of reinforced steel mesh involves several steps. It begins with selecting the appropriate grade of steel, which should provide the necessary tensile strength. The steel rods or wires used are often made from carbon steel due to its superior strength properties.

1. Cutting and Bending The steel is cut into specified lengths and then bent into the required shape. This may include creating rolls of wire or flat sheets of mesh.

2. Welding The next step is to weld the intersecting bars together. This is critical as it ensures that the mesh can maintain its structural integrity when embedded in concrete. Advanced welding techniques, such as resistance welding, are commonly employed to create strong, durable joints.

3. Quality Control Manufacturers often conduct rigorous testing to ensure that their products meet the necessary strength and safety requirements. This may include tests for tensile strength, adaptability to corrosion, and overall durability.

reinforce steel mesh manufacturers

4. Coating In some cases, protective coatings are applied to the mesh to enhance its resistance to rust and corrosion. This is especially important in regions where moisture is prevalent.

Choosing the Right Manufacturer

When selecting a reinforced steel mesh manufacturer, several factors should be considered

- Experience and Reputation Look for manufacturers with a proven track record in the industry. A well-established company is likely to have more experience and a better understanding of market needs.

- Product Range Choose manufacturers that offer a variety of mesh types and sizes, as this can provide flexibility for different construction projects.

- Certification Ensure the manufacturer holds the necessary certifications that verify compliance with quality standards.

- Customer Service Good customer service is vital. Manufacturers should provide support throughout the purchasing process, from quotation to shipment and beyond.

- Price vs. Quality While cost is an important factor, it should not compromise quality. It’s essential to strike a balance between affordability and the durability and effectiveness of the product.

Conclusion

Reinforced steel mesh plays a crucial role in construction, enhancing the strength and longevity of concrete structures. The choice of manufacturer significantly impacts the quality of the mesh and, subsequently, the safety and durability of construction works. By understanding the manufacturing process and key factors to look for, contractors and builders can make informed decisions that lead to successful project outcomes. Always prioritize quality and compliance to ensure that your construction needs are met with the best materials available.

-

Concrete Reinforcing Roll Welded Wire Mesh – Durable & High Strength Reinforcement Mesh from Leading Factories

NewsJul.05,2025

-

High Quality PVC Coated 2x1x1 Gabion Boxes - Durable, Corrosion Resistant, Direct from Manufacturer

NewsJul.05,2025

-

High Quality Roll Welded Wire Mesh for Concrete Reinforcing BWG22 Galvanized Mesh Rolls Factory Direct

NewsJul.04,2025

-

High Quality Deformed Steel Bars China - Leading Manufacturers & Suppliers

NewsJul.04,2025

-

12mm Stainless Steel Wire Mesh for Industrial & Commercial Use Top Quality Factories & Manufacturers

NewsJun.24,2025

-

Black Annealed Wire Specification - High Quality & Custom Options from Leading Factories, Suppliers, Manufacturers

NewsJun.10,2025