Aza . 14, 2024 18:02 Back to list

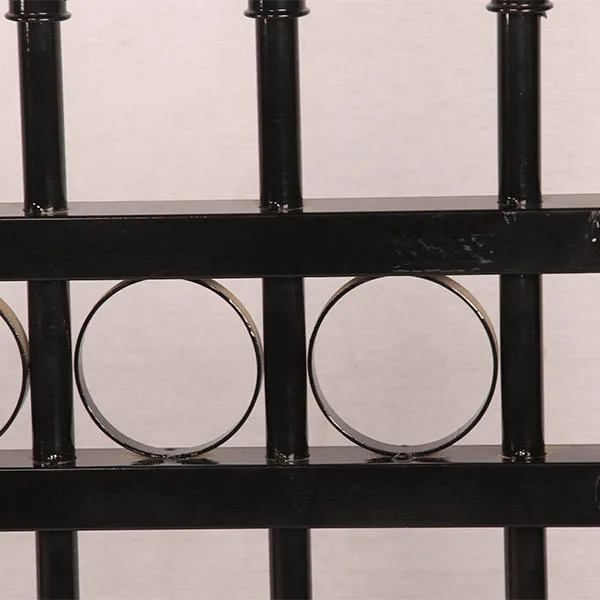

twisted bars for grating welding factory

The Evolution of Twisted Bars in Grating Welding Factories

In the realm of metal fabrication and construction, twisted bars have emerged as a significant innovation in grating welding factories. These specially designed bars not only enhance structural integrity but also streamline the welding process, making them an essential component in various industries ranging from construction to transportation. This article delves into the advantages and applications of twisted bars and explores the technological advancements in grating welding that have made them a staple in manufacturing.

What Are Twisted Bars?

Twisted bars, also known as twisted reinforcement bars, are steel bars that have been mechanically twisted, creating a helical shape along their length. This unique structure increases the overall strength and flexibility of the bars, making them ideal for numerous construction applications. The twist in the bars serves to improve adhesion with concrete, resulting in better load distribution and reduced risk of cracking or failure.

Advantages of Twisted Bars

1. Enhanced Structural Strength The twisted design significantly increases the tensile strength of the bars. This is particularly beneficial in concrete applications where the bars must withstand substantial loads. The unique geometry helps distribute stress uniformly, reducing the likelihood of weak points.

2. Improved Bonding with Concrete The helical shape creates an increased surface area for bonding with concrete. This enhanced adhesion reduces the chances of delamination and deformation under stress, ensuring a more durable and stable structure.

3. Flexibility in Design Twisted bars can be manufactured in various sizes and thicknesses, making them versatile for different projects. Their design allows for easy manipulation and installation, accommodating various structural requirements.

4. Reduced Weight Compared to standard reinforcement bars, twisted bars often weigh less while providing equivalent or superior strength. This reduction in weight can lower transportation costs and make handling during construction easier.

5. Cost-Effectiveness The inherent strength and durability of twisted bars can lead to overall reductions in material usage and labor costs in construction projects. Fewer materials may be required, and less time spent on installation can significantly impact budget considerations.

twisted bars for grating welding factory

Applications in Grating Welding Factories

Twisted bars are particularly valuable in grating welding factories, where they are used to create durable and reliable grating products. Grating is essential in various applications, including walkways, platforms, and drainage systems. The applications of twisted bars in grating production include

- Industrial Flooring Twisted bars provide robust flooring solutions for industrial settings where heavy machinery and foot traffic are common. Their strength ensures longevity in high-load environments.

- Safety Grates In places requiring safety measures, such as stairways and access points, twisted bars enhance the safety of grates. Their superior grip and strength reduce the risk of accidents.

- Custom Fabrication The adaptability of twisted bars allows grating welding factories to fabricate custom solutions tailored to specific client needs, offering unique designs while maintaining structural integrity.

Technological Advancements in Welding

The emergence of twisted bars has coincided with significant advancements in welding technology. Automated welding systems have made the process faster and more efficient, ensuring consistent quality in grating products. Computer-controlled machines can precisely manipulate twisted bars during the welding process, minimizing human error and maximizing productivity. This seamless integration of technology in grating welding production enables factories to meet the increasing demand for high-quality, durable products.

Conclusion

In conclusion, twisted bars represent a pivotal advancement in the field of grating welding factories, offering enhanced strength, durability, and flexibility. Their unique properties provide significant advantages in construction applications, making them a preferred choice among engineers and builders. As technology continues to evolve, the integration of twisted bars in the welding process will undoubtedly optimize production methods, further solidifying their place as a cornerstone in modern construction. Whether in industrial settings or custom projects, the impact of twisted bars on grating welding is profound and far-reaching.

-

Industrial-Grade Welded Wire Mesh for Factories & Suppliers | Durable

NewsJul.25,2025

-

Precision Cold Drawn Wire: High Strength & Durability Solutions

NewsJul.25,2025

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen|Durable Security Solution&Cost-Effective Fencing

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsJul.21,2025

-

Galvanized Steel Chain Link Fences-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable Corrosion-Resistant Fencing&Cost-Effective Security Solutions

NewsJul.21,2025