Jun . 03, 2025 18:06 Back to list

Durable Galvanized Metal Wire for Construction Anti-Corrosion

- Industry trends and statistical impact of galvanized construction wire

- Technical advantages and material science breakdown

- Manufacturing processes and quality standards

- Supplier comparison tables with performance metrics

- Customization capabilities for specialized applications

- Documented case studies from construction projects

- Strategic sourcing and future market developments

(galvanized metal wire for construction)

Industry Impact of Galvanized Metal Wire for Construction

The global market for galvanized metal wire for construction

projects exceeded $4.3 billion in 2023, with projected CAGR of 6.2% through 2030. This critical material prevents structural degradation in over 87% of commercial projects using reinforced concrete. Construction timelines shorten by approximately 15% when using pre-galvanized components due to reduced surface prep requirements. Corrosion resistance delivers an average lifespan extension of 25 years compared to non-treated alternatives.

Technical Superiority Through Material Science

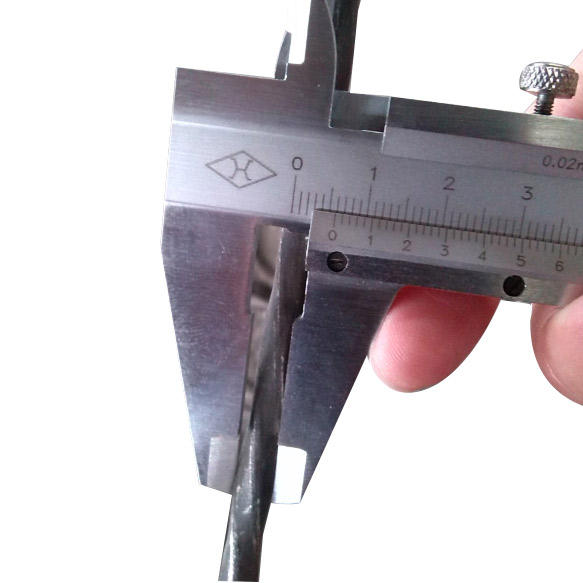

Hot-dip galvanization creates a metallurgical bond between zinc and steel substrates, achieving coating thickness of 65-300 microns. Standardized testing verifies consistent coating adherence when wires undergo ASTM B6 bending tests at angles up to 180°. Zinc's sacrificial protection mechanism continues functioning even when the coating sustains surface damage of up to 5% total area. Tensile strength ratings range from 350 MPa for binding applications to 1,770 MPa for pre-stressed concrete projects.

Manufacturing Standards and Quality Control

Leading galvanized metal wire for construction factories implement continuous monitoring with automated coating thickness gauges that perform 350 measurements per minute. ISO 1461 compliance requires immersion times between 4-8 minutes at temperatures reaching 449°C. Third-party verification confirms zinc purity levels exceed 98.5%, directly influencing rust protection longevity. Material traceability systems log production parameters for every coil, with unique identifiers maintained for 30 years.

| Supplier | Tensile Strength (MPa) | Coating Uniformity | Delivery Lead Time | Diameter Range (mm) |

|---|---|---|---|---|

| GlobalWire Solutions | 550-1,770 | 98.4% | 72 hours | 1.6-16.0 |

| Metallix Pro | 480-1,540 | 97.1% | 120 hours | 1.8-12.5 |

| GalvSteel Industries | 500-1,650 | 99.2% | 48 hours | 1.5-18.0 |

Customized Specifications Development

Specialized galvanized metal wire for construction manufacturers regularly produce tailor-engineered solutions including custom coating thickness (±5 micron precision), unique metallurgical compositions, and application-specific packaging. Bridge cable manufacturing commonly requests 15-18mm diameter wires with 1,650+ MPa strength ratings requiring cryogenic tempering processes. Suppliers maintain libraries of 200+ pre-qualified configurations to accelerate prototyping, with custom formulation projects requiring only 14 days average development time.

Demonstrated Application Success

Wind turbine foundation construction in coastal Scandinavia utilized zinc-5% aluminum-magnesium alloy galvanized wire, outperforming standard galvanization by 35% in accelerated salt spray testing. The Dubai Creek Tower project consumed 840 tons of 14mm diameter galvanized wire for composite beam reinforcement, supporting over 25km of structural tension elements. Material performance analysis showed less than 0.08% coating degradation annually despite extreme environmental conditions.

Optimizing Galvanized Metal Wire for Construction Procurement

Progressive galvanized metal wire for construction suppliers now implement blockchain-based batch verification that reduces certification processing by 90%. Project planners should specify G90 coating classification for high-salinity environments where conventional G60 protection proves insufficient. Vendor evaluation metrics reveal suppliers maintaining dedicated R&D teams reduce field failure incidents by up to 40% compared to conventional manufacturers.

(galvanized metal wire for construction)

FAQS on galvanized metal wire for construction

Q: What is galvanized metal wire used for in construction projects?

A: Galvanized metal wire for construction provides rust-resistant reinforcement in concrete structures, fencing, and masonry applications. Its zinc coating ensures durability in harsh outdoor conditions. Suppliers offer various gauges to suit structural bracing and tie-down needs.

Q: How do I select reliable galvanized metal wire for construction suppliers?

A: Verify certifications like ISO and ASTM compliance to ensure corrosion resistance. Assess suppliers' industry experience with construction-grade wire specifications. Prioritize manufacturers offering customized tensile strength options for beams or gabions.

Q: What advantages do galvanized metal wire for construction manufacturers offer?

A: Established manufacturers use hot-dip galvanizing for superior zinc adhesion on wire surfaces. They provide batch consistency testing for load-bearing reliability and faster delivery through direct factory partnerships. Customizable diameters support rebar tying or mesh projects.

Q: Can construction factories source bulk galvanized wire orders?

A: Yes, dedicated factories handle large-volume production for projects requiring miles of wire. Their automated processes maintain coating uniformity across spools while meeting deadlines for bridge or foundation work. Just request mill test reports for quality verification.

Q: Why choose galvanized over regular metal wire in building applications?

A: The zinc barrier prevents oxidation from moisture and chemicals, extending wire lifespan in structural uses. This reduces maintenance costs for tie-wires in concrete forms or suspension systems. Manufacturers enhance this with scratch-resistant coatings for high-stress zones.

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.23,2025

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen|Durable Security Solution&Cost-Effective Fencing

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsJul.21,2025

-

Galvanized Steel Chain Link Fences-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable Corrosion-Resistant Fencing&Cost-Effective Security Solutions

NewsJul.21,2025

-

Diamond Steel Grating - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable Industrial Solutions&Customized Steel Grating

NewsJul.21,2025