Dic . 20, 2024 07:13 Back to list

6mm-12mm wire gauge cold drawn wire factories

The Significance of 6mm-12mm Wire Gauge Cold Drawn Wire Factories

In the realm of manufacturing and construction, the importance of high-quality materials cannot be overstated. Among these, cold drawn wire stands out as a critical component in various applications. Factories that produce 6mm to 12mm wire gauge cold drawn wire play a significant role in ensuring the availability of durable, reliable, and precisely engineered materials for diverse industries.

Understanding Cold Drawn Wire

Cold drawn wire is produced through the process of drawing metal through a series of dies at room temperature. This method not only enhances the mechanical properties of the wire but also allows for increased uniformity in dimensions. As a result, cold drawn wire is known for its superior tensile strength, surface finish, and dimensional accuracy compared to wire produced through other methods like hot rolling.

Applications of 6mm to 12mm Cold Drawn Wire

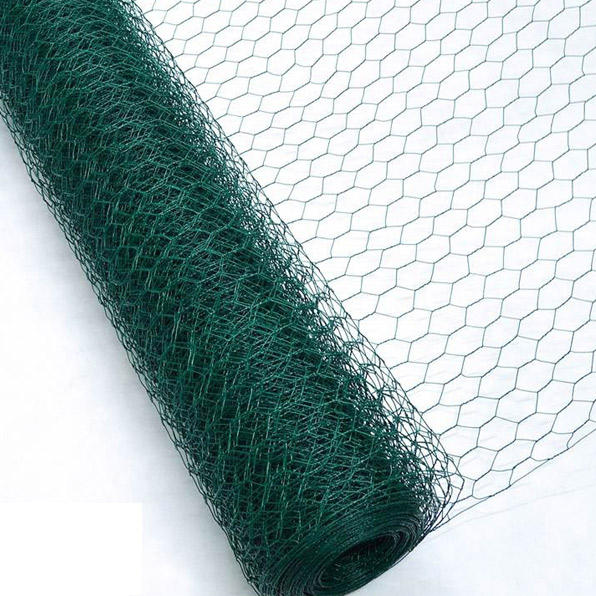

Wire within the 6mm to 12mm gauge range is particularly versatile and finds applications across various industries. In the construction sector, this wire is often used for reinforcing concrete structures, fabricating wire mesh, and producing anchor bolts. Its robustness ensures that it can withstand significant loads, making it ideal for structural applications.

In the automotive industry, cold drawn wire is utilized in the manufacturing of springs, cables, and other components that require high tensile strength and resilience. Similarly, the electrical industry benefits from this wire for producing wiring and connectors, as the precise dimensions and excellent conductivity of cold drawn wire meet stringent international standards.

Furthermore, manufacturers of consumer goods rely on cold drawn wire for the production of small parts and components. The accuracy in size and finish allows for seamless integration into products, ensuring functionality and aesthetic appeal. As diverse as these applications are, they highlight the necessity for high-quality wire produced in specialized factories.

The Manufacturing Process

6mm-12mm wire gauge cold drawn wire factories

The production of 6mm to 12mm wire gauge cold drawn wire involves several key stages. First, raw materials, typically high-carbon steel or stainless steel, are sourced, ensuring that they meet specific quality standards. The initial step in the production process is wire rod preparation. The wire rods are cleaned and cut to the desired lengths before being pre-treated to remove any impurities.

The main stage of the process involves drawing the wire through various dies. Each die reduces the diameter of the wire while increasing its length, and this is meticulously controlled to achieve the desired gauge and surface quality. Through multiple passes, manufacturers can refine the wire to the exact specifications needed by their customers.

After drawing, the wire undergoes heat treatment processes such as annealing, which enhances its ductility and toughness. Finally, the wire is precisely cut, packaged, and prepared for distribution. This rigorous manufacturing process contributes to the consistent quality and reliability expected from 6mm to 12mm cold drawn wire.

Quality Assurance and Standards

Quality control is paramount in cold drawn wire production. Factories adhere to industry standards and undergo regular inspections to ensure that their products meet the required specifications. This includes testing for tensile strength, elongation, and surface quality. Certifications such as ISO ensure that the processes and products are in line with international best practices, giving customers confidence in the materials they are purchasing.

The Future of Cold Drawn Wire Factories

As industries evolve, the demand for high-quality cold drawn wire will continue to grow. Innovations in manufacturing technologies and materials science will likely lead to even more efficient production methods and enhanced wire properties. Furthermore, the push toward sustainable manufacturing practices may encourage factories to adopt eco-friendly processes and materials, aligning with global efforts to reduce environmental impact.

In conclusion, 6mm to 12mm wire gauge cold drawn wire factories are integral to countless industries, providing essential materials that form the backbone of modern infrastructure and manufacturing. The combination of advanced production techniques, rigorous quality control, and diverse applications makes cold drawn wire a critical focus of industrial growth and innovation. As we look ahead, these factories will undoubtedly play a significant role in supporting the future of manufacturing and construction.

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025