okt . 30, 2024 14:52 Back to list

oem welded wire mesh in concrete slab

The Role of OEM Welded Wire Mesh in Concrete Slabs

In the realm of construction, the integrity of concrete structures significantly hinges on the materials and methods employed during their formulation. One critical component that enhances the durability and resilience of concrete slabs is welded wire mesh, particularly when utilized as an Original Equipment Manufacturer (OEM) product. This article delves into the importance of OEM welded wire mesh in concrete slabs, its benefits, and its applications.

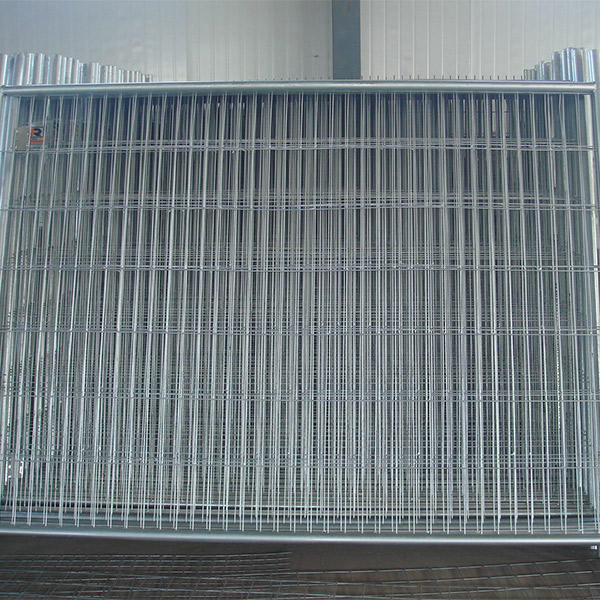

Welded wire mesh consists of many wire strands arranged in a grid pattern, which are then welded at their intersections. The use of this material has become increasingly popular in construction due to its mechanical properties and structural advantages. By incorporating welded wire mesh into concrete slabs, builders can considerably improve load-bearing capacity and reduce the likelihood of cracking.

One of the primary benefits of OEM welded wire mesh is its ability to evenly distribute loads across the surface of the concrete. This distribution minimizes stress concentrations that can lead to structural failures. In environments where heavy loads are common—such as industrial floors or pavements—this evenly spread support is crucial in maintaining the integrity of the slab over time.

Moreover, OEM welded wire mesh offers increased tensile strength compared to traditional reinforcement methods, such as steel bars. This is primarily due to the seamless integration of the mesh within the concrete. As the concrete cures, it bonds with the mesh, creating a composite material that harnesses the strengths of both components. As a result, the welded wire mesh enhances the ductility of the concrete, allowing for some flexibility under load which is essential for preventing catastrophic failure.

oem welded wire mesh in concrete slab

Durability is another compelling reason for the popularity of OEM welded wire mesh in concrete applications. The mesh is typically made from high-strength steel that is resistant to corrosion. This characteristic makes it particularly suitable for outdoor applications or in environments where moisture exposure is a concern. By preventing the ingress of water, welded wire mesh helps to extend the lifespan of concrete slabs, thus reducing maintenance costs and extending the lifecycle of the structures.

OEM manufactured welded wire mesh also adheres to specific industry standards, ensuring consistency in quality and performance. By sourcing from reputable OEM suppliers, construction firms can trust that they are using a product that meets rigorous specifications tailored for their particular application. This standardization not only simplifies the procurement process but also enhances project reliability.

Another aspect to consider is the versatility of welded wire mesh. It can be customized in terms of wire diameter, mesh spacing, and sheet sizes, making it suitable for a range of construction projects—from residential driveways to large industrial floors. This adaptability allows engineers and architects to design concrete slabs that meet specific load requirements or aesthetic outcomes without compromising on safety.

In conclusion, the integration of OEM welded wire mesh in concrete slabs is a decision driven by the need for improved structural performance, durability, and versatility. Understanding its benefits can greatly influence construction methodologies and outcomes, ultimately leading to more robust and long-lasting concrete structures. As the construction industry continues to evolve, the reliance on effective reinforcement solutions like welded wire mesh will undoubtedly play a significant role in achieving superior engineering feats.

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025