Dez . 12, 2024 14:05 Back to list

hot-dipped galvanized iron wire

Understanding Hot-Dipped Galvanized Iron Wire Characteristics, Applications, and Advantages

Hot-dipped galvanized iron wire has gained significant recognition in various industries due to its exceptional durability and resistance to corrosion. This wire is created through a process that involves coating iron or steel with a protective layer of zinc. This article will delve into what hot-dipped galvanized iron wire is, the process of its production, its diverse applications, and the benefits it offers.

What is Hot-Dipped Galvanized Iron Wire?

Hot-dipped galvanized iron wire is a type of wire that undergoes a galvanization process, wherein it is submerged in a bath of molten zinc. This treatment produces a thick and robust coating that adheres strongly to the iron, offering a high level of protection against rust and wear. The hot-dipping process ensures that every part of the wire is coated uniformly, including any intricate shapes or structures.

The Production Process

The production of hot-dipped galvanized iron wire involves several key steps

1. Cleaning the Wire The initial step includes cleaning the iron wire to remove any grease, dirt, or oxidation. This is typically done using an acid solution.

2. Fluxing After cleaning, the wire is treated with a flux solution, which helps in the adhesion of zinc during the coating process.

3. Galvanization The cleaned and fluxed wire is dipped into a molten zinc bath. The temperature of the molten zinc typically ranges between 450°C and 460°C. The wire remains in the bath for a specific period, allowing the zinc to coat the wire thoroughly.

4. Cooling and Inspection Once coated, the wire is removed from the zinc bath and cooled. Subsequent inspections ensure that the coating meets specific thickness and quality standards.

5. Packaging Finally, the wire is packaged for distribution, ensuring that it arrives at its destination in optimal condition.

Applications of Hot-Dipped Galvanized Iron Wire

The versatility of hot-dipped galvanized iron wire makes it suitable for a wide range of applications

hot-dipped galvanized iron wire

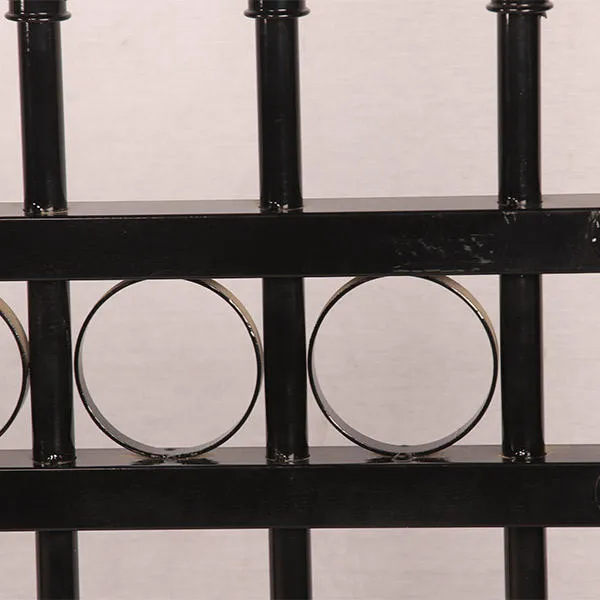

1. Construction It is commonly used in construction for fencing, wire meshes, and reinforcement in concrete structures. Its resistance to corrosion is particularly beneficial in outdoor environments.

2. Agriculture Farmers often use galvanized wire for fencing livestock and securing crops against wildlife. Additionally, it’s used in trellising plants, providing strong support that stands against the elements.

3. Manufacturing In the manufacturing sector, this wire is utilized to produce various products such as barbed wire, chain link fences, and other wire products that require durability.

5. DIY Projects For home improvement enthusiasts, hot-dipped galvanized wire is a popular choice for craft and DIY projects due to its strength and corrosion resistance.

Advantages of Hot-Dipped Galvanized Iron Wire

The advantages of using hot-dipped galvanized iron wire are numerous

1. Corrosion Resistance One of the most significant benefits is its outstanding resistance to rust and corrosion. The zinc coating acts as a barrier that protects the iron beneath, extending the life of the wire.

2. Cost-Effective Although the initial cost may be higher than non-galvanized alternatives, the longevity and reduced maintenance needs of galvanized wire make it a cost-effective choice in the long run.

3. Durability It can withstand various environmental conditions, including extreme temperatures and moisture, making it suitable for outdoor applications.

4. Ease of Use Hot-dipped galvanized iron wire is easy to handle and manipulate, which is advantageous for various construction and agricultural tasks.

5. Aesthetic Appeal The smooth, shiny finish of galvanized wire contributes to an appealing appearance, making it suitable for visible structures or fencing.

In conclusion, hot-dipped galvanized iron wire is an essential material in modern industries, offering remarkable properties that enhance its performance across multiple applications. Its corrosion resistance, longevity, and versatility make it a favored choice for builders, farmers, and manufacturers alike. Whether for construction, agriculture, or DIY projects, understanding the benefits and applications of this material can lead to more efficient and cost-effective practices.

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025