Gor . 04, 2025 11:07 Back to list

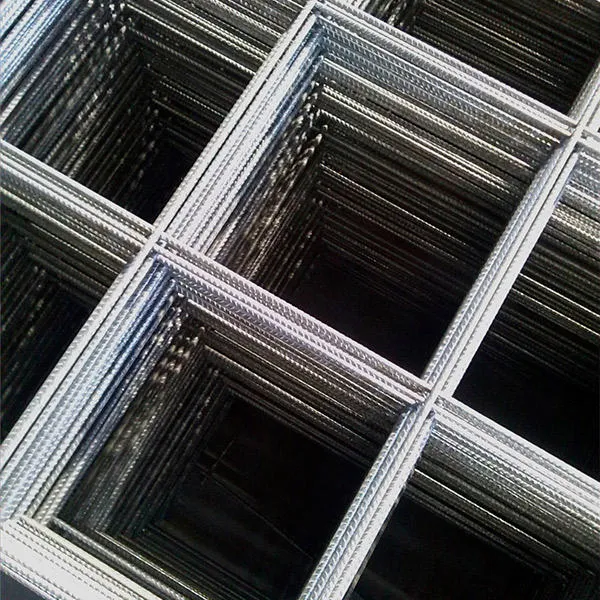

High Quality Roll Welded Wire Mesh for Concrete Reinforcing BWG22 Galvanized Mesh Rolls Factory Direct

- Introduction to Roll Welded Wire Mesh: Definition, Types, and Industry Relevance

- Technical Specifications and Performance Advantages

- Comparative Analysis of Leading Factories and Suppliers

- Customization Options: Tailoring Welded Wire Mesh Solutions

- Application Scenarios: Real-World Case Studies

- Market Trends and Future Prospects for Welded Wire Mesh Solutions

- Conclusion: Choosing the Right Roll Welded Wire Mesh Supplier for Your Project

(roll welded wire mesh)

Introduction to Roll Welded Wire Mesh: Definition, Types, and Industry Relevance

Roll welded wire mesh has cemented its position as a cornerstone in modern infrastructure development. Created by longitudinal and transverse wires laid at precise right angles and electrically welded at each intersection, this mesh is manufactured on cutting-edge machinery to prioritize uniformity and durability. The versatility of roll welded wire mesh

extends across residential, commercial, and industrial applications, including concrete reinforcement, fencing, animal enclosures, and safety barriers. As demand for high-strength, efficient, and sustainable reinforcement solutions surges, global consumption is projected to exceed 15 million tons by 2026, signifying a sustained CAGR of 4.3%. Within this domain, distinguished offerings include concrete reinforcing roll welded wire mesh for structural projects and specialized variants like bwg22 galvanized welded wire mesh 30m rolls for corrosion resistance and extended service life. Suppliers and factories worldwide are refining their processes to meet increasing engineering standards, emphasizing reliability, safety, and cost-efficiency.

Technical Specifications and Performance Advantages

Cutting-edge quality and adherence to international standards distinguish high-performance welded wire mesh products. The most widely selected mesh for concrete reinforcement, for example, features wire diameters ranging between 2.5mm and 6mm, mesh sizes from 25x25mm up to 200x200mm, and roll widths adapted from 1m to 2.4m. The bwg22 galvanized welded wire mesh 30m roll is particularly valued for its blend of flexibility, light weight (approximately 1.62 kg/m² for BWG22 at 2-inch mesh), and robust zinc-coating of up to 60g/m², which achieves a corrosion resistance lifespan of up to 15 years in typical outdoor environments. Steel grade, surface finish, and weld strength are all controlled by precision automation, resulting in high dimensional accuracy (±2mm for cut length and width). Enhanced performance metrics such as tensile strength (typically ≥ 480 N/mm²), minimal elongation (under 2% at break), and low deviation rates (weld failure under 1 per 10,000 welds) further highlight the suitability of these meshes for demanding use cases, including heavy traffic civil infrastructure and marine works.

Comparative Analysis of Leading Factories and Suppliers

Selecting the right source for concrete reinforcing roll welded wire mesh products requires a detailed understanding of manufacturing capacities, quality assurance practices, and global logistics capabilities. The table below summarizes a comparison of key parameters among major bwg22 galvanized welded wire mesh 30m roll factories and suppliers:

| Parameter | Factory A | Supplier B | Factory C |

|---|---|---|---|

| Annual Production Capacity (tons) | 45,000 | 36,000 | 54,000 |

| Wire Diameter Range (mm) | 1.2 - 6.0 | 1.0 - 5.5 | 1.4 - 8.0 |

| Galvanizing Method | Hot-Dip Galvanized | Electro-Galvanized | Hot-Dip Galvanized |

| Mesh Roll Lengths (m) | 15, 25, 30 | 20, 25, 30 | 10, 20, 30 |

| Delivery Time (days) | 18 | 21 | 15 |

| Major Export Markets | USA, Europe, Middle East | Europe, Australia, Africa | North America, Middle East, SE Asia |

| Product Certifications | ISO 9001, CE | ISO 9001 | ISO 9001, ASTM |

| Average Complaint Rate (%) | 0.2 | 0.5 | 0.1 |

| Customization Capability | High | Medium | High |

As shown, Factory C excels in scale, speed, and compliance, followed closely by Factory A. Supplier B provides regional flexibility but slightly lags in quality metrics and customization. International buyers consistently cite stringent certification, lead time, and tailored production as primary selection criteria. Moreover, shrewd procurement teams scrutinize not just quoted prices but also post-sales support, on-time delivery rates, and the flexibility to fulfill OEM/ODM requests.

Customization Options: Tailoring Welded Wire Mesh Solutions

The adaptability of roll welded wire mesh is pivotal to supporting novel construction methodologies and addressing project-specific challenges. Customization services offered by reputable concrete reinforcing roll welded wire mesh suppliers typically encompass:

- Wire Diameter: Provision of non-standard gauges (ranging from BWG16 to BWG24) for specialized strength or flexibility requirements.

- Mesh Size: Fabrication to bespoke square or rectangular openings, from dense 10x10mm up to 200x200mm for both minimal and heavy-duty load-bearing.

- Roll Dimensions: Tailoring both width and length, including wide-format (up to 2.5m width) or ultra-long rolls (up to 50m), minimizing overlaps and labor costs onsite.

- Surface Treatment: Optional upgrades such as PVC-coating, heavy zinc-coating, or custom powder finishes for aggressive environments.

- Edge Finishing: Choice of cut, bent, or hemmed edges for safety and installation efficiency.

- Packaging: Rolls supplied with customer-specified labeling, color coding, or export-safe pallets to accommodate complex logistics chains.

State-of-the-art production lines utilize programmable logic controllers (PLCs) and high-speed resistance welding—enabling fully tailored batch runs with zero tolerance for deviation. For major infrastructure projects, reputable bwg22 galvanized welded wire mesh 30m roll factories offer co-engineering services, including CAD design, pre-delivery assembly trials, and even on-site technical support, ensuring installation precision and project timeline adherence.

Application Scenarios: Real-World Case Studies

The deployment of roll welded wire mesh spans across the civil, industrial, agricultural, and energy sectors, with tangible benefits validated through completed projects.

- High-Rise Concrete Slab Reinforcement (Singapore, 2023): Switch to roll mesh reduced rebar labor hours by 28% and improved on-site safety metrics by 40%. Concrete curing times decreased by 10%, expediting overall project delivery.

- Coastal Highway Embankment (Oman, 2022): BWG22 galvanized mesh with 30m rolls was used to form a foundational geogrid, demonstrating a 19% cost reduction in maintenance over five years compared to traditional materials.

- Poultry Enclosure (Argentina, 2021): Custom 12x55mm mesh delivered a 45% improvement in predator-proofing for commercial farms, while PVC-coated variants increased mesh life expectancy to 20 years.

- Storage Depot Safety Fencing (UK, 2022): Installation of roll welded mesh streamlined perimeter security installation (with over 5,000m deployed in nine days), providing over 99% post-project client satisfaction due to ease of handling and minimal post-maintenance.

These cases underscore the measurable advantages of switching to high-quality, professionally tailored welded wire mesh in roll format: faster installation, improved safety, superior longevity, and optimized lifecycle costs.

Market Trends and Future Prospects for Welded Wire Mesh Solutions

Advances in materials science, process automation, and digital project management are reshaping the welded wire mesh industry. Recent research predicts the global welded wire mesh market will grow to $8.7 billion by 2026, with structural concrete applications accounting for nearly 62% of total demand. Smart factory initiatives, including real-time quality monitoring and digitally enabled customization portals, are empowering buyers and reducing lead times by up to 30%. Environmental regulations are prompting a shift towards environmentally friendly galvanizing techniques, with nearly 50% of new suppliers adopting eco-zinc technologies. Simultaneously, integration of recycled steel into mesh production is increasing, set to reach 18% of total production volume by 2026. Within emerging economies, infrastructure stimulus plans are expected to accelerate demand for cost-effective reinforcement, making supplier agility and technical partnership more critical than ever.

Conclusion: Choosing the Right Roll Welded Wire Mesh Supplier for Your Project

Selecting a roll welded wire mesh partner is a strategic decision that directly impacts project economics, safety standards, and long-term durability. Prioritize suppliers and factories combining high-capacity production, strict quality assurance, customization prowess, and positive client track records. Whether opting for a concrete reinforcing roll welded wire mesh supplier or a bwg22 galvanized welded wire mesh 30m roll factory, robust technical support, rapid logistics, and traceable certifications are essential. Empower your construction or industrial project with modern welded wire mesh–engineered for tomorrow’s challenges, today.

(roll welded wire mesh)

FAQS on roll welded wire mesh

Q: What is roll welded wire mesh used for?

A: Roll welded wire mesh is mainly used for reinforcing concrete in construction projects. It improves durability and structural integrity. It's also popular for fencing and animal enclosures.Q: How do I choose a reliable concrete reinforcing roll welded wire mesh supplier?

A: Look for suppliers with industry certifications and positive customer feedback. Ensure they offer consistent quality and timely delivery. Comparing prices and technical support is also recommended.Q: What are the main features of bwg22 galvanized welded wire mesh 30m rolls?

A: BWG22 galvanized welded wire mesh in 30m rolls features rust resistance, uniform wire thickness, and strong welding. It is commonly used for both industrial and agricultural applications. The 30m roll offers easy handling and installation.Q: Can I order custom sizes from a bwg22 galvanized welded wire mesh 30m roll factory?

A: Yes, most factories accept custom size and specification orders based on your project needs. It's best to discuss your requirements directly with the manufacturer. Custom orders may affect pricing and lead time.Q: What should I consider when buying from bwg22 galvanized welded wire mesh 30m roll factories?

A: Check the factory’s quality control, production capacity, and shipping options. Ask for product samples or test reports for assurance. Reliable factories provide good after-sales support and documentation.-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025