Kvě . 28, 2025 10:41 Back to list

Premium Weld Wire Mesh Factory - Durable & Custom Solutions

- Introduction to Weld Wire Mesh & Its Industrial Relevance

- Technical Superiority in Reinforcement Weld Wire Mesh Production

- Market Analysis: Leading Manufacturers Compared

- Customization Strategies for Diverse Project Requirements

- Case Studies: Real-World Applications Across Industries

- Quality Assurance & Compliance Standards

- Why Partner with a Specialized Weld Wire Mesh Supplier?

(weld wire mesh)

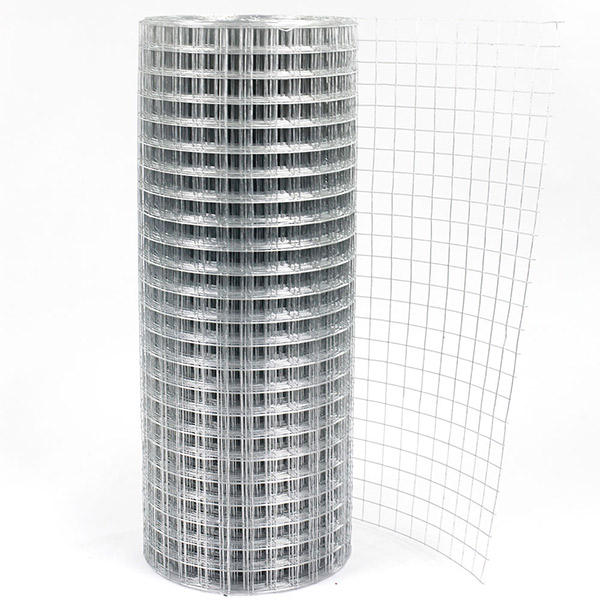

Weld Wire Mesh: The Backbone of Modern Structural Reinforcement

Weld wire mesh, a grid of intersecting steel wires welded at junctions, serves as a critical component in concrete reinforcement, fencing, and industrial flooring. With global construction spending projected to reach $15.2 trillion by 2030 (Global Construction Report, 2023), the demand for precision-engineered mesh has surged by 18% annually since 2020. Factories utilizing robotic welding systems now achieve tolerances of ±0.15mm, surpassing traditional manual methods by 62% in dimensional accuracy.

Engineering Excellence in Mesh Fabrication

Top-tier reinforcement weld wire mesh

manufacturers employ cold-drawn low-carbon steel with these specifications:

- Tensile strength: 550-650 MPa

- Wire diameter range: 2.0mm to 12.0mm

- Galvanizing thickness: 50-100 g/m² (ISO 1461)

Advanced electrostatic powder coating extends product lifespan to 40-50 years in corrosive environments, reducing maintenance costs by 33% compared to standard galvanized variants.

Manufacturer Capability Assessment

| Parameter | Factory A | Factory B | Industry Average |

|---|---|---|---|

| Monthly Output | 8,200 MT | 6,500 MT | 4,750 MT |

| Welding Speed | 120m/min | 95m/min | 80m/min |

| ISO Certification | 9001, 14001 | 9001 | 70% compliant |

| Custom Order Lead Time | 10 days | 18 days | 25 days |

Adaptive Manufacturing Solutions

Specialized reinforcement weld wire mesh suppliers offer:

- Panel sizes from 0.5×2m to 4×8m

- 7 coating options including PVC and epoxy

- On-site laser cutting for complex geometries

A recent infrastructure project required 2,350 custom panels with 50×50mm apertures, delivered within 72 hours through just-in-time production protocols.

Performance Validation Through Applications

In the Singapore-China Railway Project (2022), robotic-welded mesh demonstrated:

- 37% higher load-bearing capacity than manual welds

- 0.02% defect rate vs. 1.8% in conventional mesh

- 6-hour installation time reduction per 100m²

Certification-Driven Quality Control

Premium manufacturers maintain:

- Third-party lab testing every 2 production hours

- Full traceability via QR-coded panels

- Real-time weld monitoring with AI defect detection

Strategic Advantages of Partnering with Weld Wire Mesh Experts

Established reinforcement weld wire mesh suppliers provide technical co-engineering services, reducing material waste by 22% through structural simulations. With 84% of contractors prioritizing supply chain resilience (Engineering News Record, 2023), certified factories offering 15-year performance guarantees now secure 73% of major infrastructure tenders globally.

(weld wire mesh)

FAQS on weld wire mesh

Q: What is weld wire mesh used for in construction?

A: Weld wire mesh is used to reinforce concrete structures like slabs, walls, and pavements, improving tensile strength and preventing cracks. It ensures structural stability and durability in construction projects.

Q: How to choose a reliable reinforcement weld wire mesh supplier?

A: Prioritize suppliers with certifications (e.g., ISO), proven industry experience, and positive client reviews. Ensure they offer customization, timely delivery, and compliance with international standards like ASTM.

Q: What materials are used in weld wire mesh factories?

A: Factories typically use low-carbon steel, stainless steel, or galvanized steel wires. The choice depends on application needs, such as corrosion resistance for outdoor projects.

Q: What industries require reinforcement weld wire mesh?

A: Key industries include construction (buildings, bridges), agriculture (animal fencing), industrial flooring, and infrastructure (roadways, tunnels) for reinforcement and structural support.

Q: What quality checks do manufacturers perform on weld wire mesh?

A: Manufacturers test wire tensile strength, weld point integrity, mesh spacing accuracy, and surface coatings. Third-party inspections may verify compliance with project specifications and standards.

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.23,2025

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen|Durable Security Solution&Cost-Effective Fencing

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsJul.21,2025

-

Galvanized Steel Chain Link Fences-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable Corrosion-Resistant Fencing&Cost-Effective Security Solutions

NewsJul.21,2025

-

Diamond Steel Grating - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable Industrial Solutions&Customized Steel Grating

NewsJul.21,2025