Pro . 24, 2024 03:51 Back to list

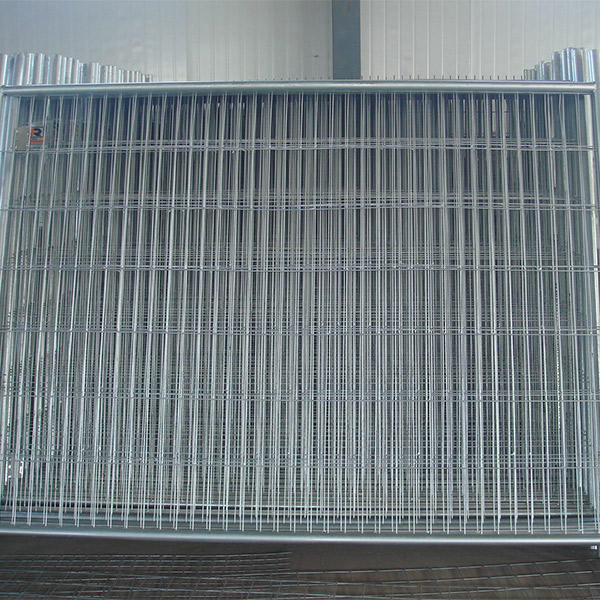

galvanized steel wire factory

The Importance of Galvanized Steel Wire Factories in Modern Industry

Galvanized steel wire has emerged as a vital product in numerous industries, owing to its enhanced durability and resistance to corrosion. This type of wire undergoes a galvanization process, where it is coated with a layer of zinc to protect it from environmental elements. This article explores the significance of galvanized steel wire factories, their production processes, technological advancements, and the diverse applications for their products.

The Production Process

The manufacturing of galvanized steel wire begins with high-quality steel wire rods. These rods are carefully drawn to the required thickness, ensuring uniformity in diameter. After drawing, the rods are cleaned to remove any scale or impurities, essential for effective galvanization. The next step involves immersing the wire in a molten zinc bath, allowing the zinc to bond with the steel surface. This process, known as hot-dip galvanization, guarantees a robust protective layer that significantly improves the wire's longevity.

After galvanization, the wire is dried and often subjected to additional processes, such as annealing, which enhances its ductility and strength. Quality control is rigorous, with various tests conducted to ensure that the galvanized steel wire meets industry standards for tensile strength, corrosion resistance, and flexibility. Factories employ modern machinery and skilled technicians to monitor every stage of production meticulously.

Technological Advancements

In recent years, galvanized steel wire factories have adopted advanced technologies to optimize production efficiency and product quality. Automation plays a key role, reducing manual labor while increasing precision in the manufacturing process. Automated machinery can consistently produce large volumes of wire with minimal defects, ensuring that the products meet the demands of various industries.

Furthermore, innovative galvanization techniques, such as electro-galvanization, have emerged, providing a thinner but equally protective zinc coating. This method is particularly advantageous for applications where weight reduction is critical, such as in the automotive industry. The integration of Industry 4.0 technologies has also facilitated real-time monitoring of production processes, enabling factories to quickly address any issues that may arise.

galvanized steel wire factory

Diverse Applications of Galvanized Steel Wire

Galvanized steel wire is versatile and finds applications across various sectors. In the construction industry, it is widely used for fencing, reinforcing concrete, and tying structural elements together. The wire’s corrosion resistance makes it ideal for outdoor applications, where it is exposed to moisture and environmental wear.

Additionally, the agriculture sector benefits from galvanized steel wire for fencing livestock and securing crops. Its durability ensures that agricultural structures can withstand harsh weather conditions, enhancing farm productivity and sustainability. Furthermore, the manufacturing sector utilizes galvanized wire in the production of springs, clips, and other components that require materials with high tensile strength and resilience.

Environmental Considerations

As industries become more environmentally conscious, galvanized steel wire factories are adopting sustainable practices. Utilizing recycled materials in the production process, reducing waste, and implementing energy-efficient manufacturing practices are becoming standard. This commitment to sustainability not only benefits the environment but also enhances the reputation of manufacturers in a competitive market.

Conclusion

Galvanized steel wire factories play a crucial role in supporting various industries with high-quality, durable products that meet the diverse needs of modern applications. Through continuous technological advancements and a commitment to sustainability, these factories are poised to remain essential contributors to the global economy, ensuring that the infrastructure of tomorrow is built on strong foundations. As demand for reliable and corrosion-resistant materials grows, the importance of galvanized steel wire will only continue to rise, cementing its status as a cornerstone of industrial materials.

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025