Pro . 04, 2024 02:31 Back to list

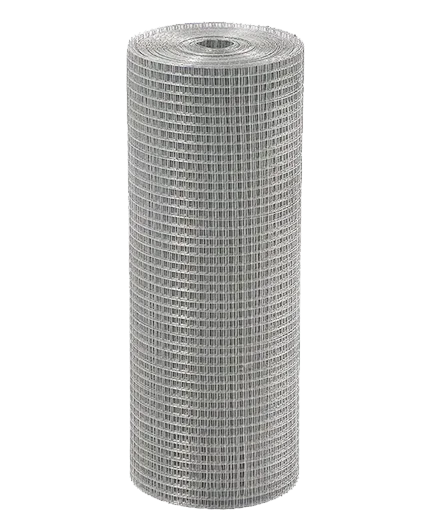

6mm welded panel factory

The Importance of 6mm Welded Panels in Modern Manufacturing A Comprehensive Overview

In the landscape of modern manufacturing, the choice of materials and construction techniques plays a pivotal role in determining the durability, functionality, and cost-effectiveness of products. Among various materials, welded panels, particularly those measuring 6mm in thickness, have emerged as a popular choice across numerous industries. This article delves into the significance of 6mm welded panels, exploring their production process, advantages, applications, and the role of factories dedicated to their manufacture.

Understanding Welded Panels

Welded panels are essentially flat sheets of material that are interconnected using welding techniques to form a sturdy structure. The welding process enhances the strength of the panels, making them suitable for demanding applications. Panels are commonly made from metals such as steel and aluminum, which offer different properties and benefits. The 6mm thickness represents a balance between strength and weight, providing structural integrity without being excessively heavy or cumbersome.

Manufacturing Process

The production of 6mm welded panels typically involves several key steps. Initially, raw materials are sourced and prepared. These materials are cut to size before undergoing the welding process, where they are joined together using techniques such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding, depending on the specific requirements of the application.

Once the panels are welded, they undergo rigorous quality assurance tests to ensure they meet industry standards. This may include inspections for structural integrity, corrosion resistance, and overall finish quality. Advanced factories often integrate automated systems, enhancing precision and reducing production time, ultimately leading to higher efficiency and reduced costs.

Advantages of 6mm Welded Panels

1. Durability One of the primary advantages of 6mm welded panels is their durability. The welding process creates strong joints that can withstand substantial stress and strain, making them ideal for heavy-duty applications.

2. Corrosion Resistance Many factories treat welded panels with protective coatings or use corrosion-resistant materials, ensuring longevity even in harsh environments. This feature is particularly critical for applications in construction, marine, and outdoor settings.

6mm welded panel factory

3. Versatility 6mm welded panels can be customized to fit various design specifications, making them suitable for diverse applications, from industrial machinery casing to decorative architectural elements.

4. Cost-Effectiveness While the initial investment in welded panels may be slightly higher compared to other materials, their longevity and reduced maintenance costs make them a cost-effective choice in the long run.

Applications of 6mm Welded Panels

The versatility of 6mm welded panels enables their use across a wide range of sectors. In the construction industry, they are often utilized for fencing, wall panels, and roofing structures, providing both aesthetic and structural benefits. In the automotive and aerospace industries, these panels are used to create lightweight yet robust components that enhance performance.

Moreover, welded panels are gaining traction in the agricultural sector for creating sturdy barriers and storage units. Their ability to withstand environmental stresses further solidifies their position as a staple material across industries.

The Role of Factories in Manufacturing

Dedicated factories play a crucial role in the production of 6mm welded panels. These establishments not only provide the necessary machinery and technology but also ensure skilled craftsmanship through a trained workforce. Continuous innovation within these factories, including the adoption of new welding techniques and automated production lines, enhances the efficiency of the manufacturing process.

Moreover, factories are increasingly focusing on sustainable practices, utilizing eco-friendly materials and recycling waste to minimize the environmental impact of their operations. This shift towards sustainability aligns with global trends, reflecting a growing awareness of corporate responsibility in manufacturing.

Conclusion

The prominence of 6mm welded panels in modern manufacturing can be attributed to their unique combination of strength, versatility, and cost-effectiveness. As industries continue to evolve, the demand for these robust panels is likely to increase. With factories dedicated to high-quality production, the future of 6mm welded panels looks promising, paving the way for innovative applications across various sectors. By embracing advancements in technology and sustainability, manufacturers can ensure that welded panels remain a vital component in the ever-evolving landscape of industry.

-

Black Annealed Wire Specification - High Quality & Custom Options from Leading Factories, Suppliers, Manufacturers

NewsJun.10,2025

-

High-Quality 18 Gauge Black Steel Wire Reliable Factories & Suppliers

NewsJun.10,2025

-

Chain Link Fence Gates - Durable & Secure Access Solutions

NewsJun.10,2025

-

Premium Cold Rolled Steel Bar Supplier High Strength & Precision

NewsJun.10,2025

-

Galvanized Wire Brick Force Mesh - Corrosion Resistant

NewsJun.09,2025

-

Galvanized Metal Wire for Construction Strong & Corrosion-Resistant

NewsJun.09,2025