Jan . 01, 2025 13:39 Back to list

Wire Mesh Roll Manufacturers and Their Product Offerings for Various Industries

Exploring the World of Wire Mesh Rolls Factories

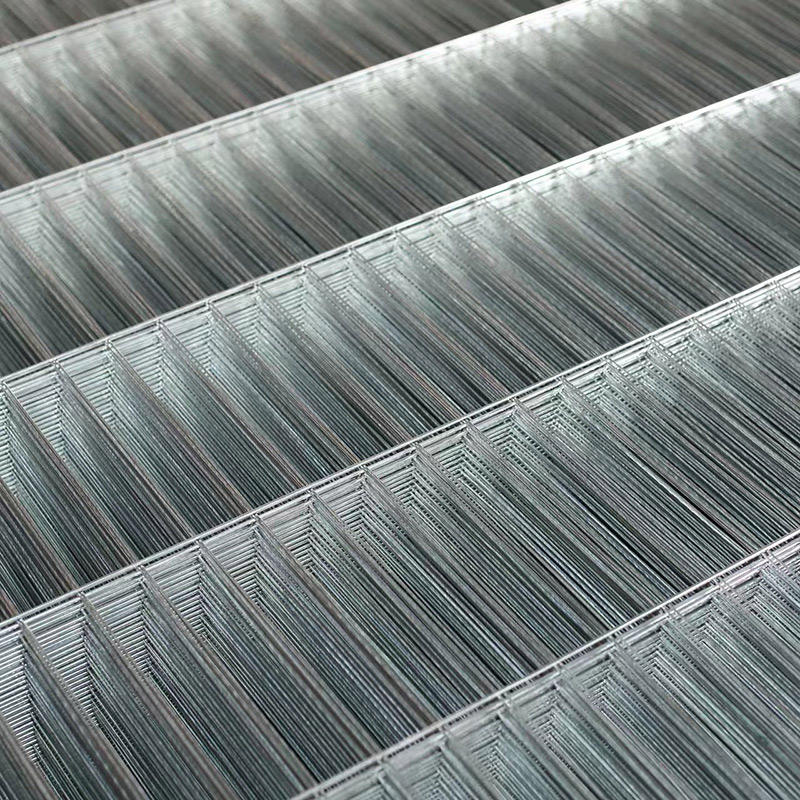

Wire mesh rolls have become an essential component across various industries, ranging from construction to agriculture, and even in household applications. The production of these wire mesh rolls is a complex process, and understanding the factories that manufacture them provides crucial insight into their significance and versatility.

The Basics of Wire Mesh

Wire mesh is made from metal wires that are woven together to create a grid-like structure. It is available in various materials, including stainless steel, aluminum, and galvanized steel, catering to different needs and environments. This versatility makes wire mesh a preferred choice for a myriad of applications.

Manufacturing Process in Wire Mesh Rolls Factories

The production of wire mesh rolls begins with the selection of raw materials. Factories often source high-quality steel or other metal wires, which are then processed and treated to meet the specific requirements of different applications. The process typically involves several key steps

1. Wire Drawing The first step in manufacturing wire mesh rolls is drawing the raw metal through a series of dies to produce wire of specific gauges. This step is crucial as it determines the strength and flexibility of the final product.

2. Welding or Weaving After drawing, the wires are either welded or woven together to form mesh panels. Welding provides a stronger bond and is preferred for applications requiring higher durability, while weaving is often used for lighter applications.

3. Finishing Treatments Once the wire mesh is formed, the panels undergo various finishing treatments. This might include galvanization, powder coating, or plastic coating, which enhance corrosion resistance and improve the aesthetic appeal of the mesh.

4. Cutting and Rolling The final step involves cutting the mesh into desired dimensions and rolling it into manageable rolls for transport and storage. Factories often offer customization options, allowing clients to request specific sizes and properties.

Quality Control in Production

wire mesh rolls factories

Quality control is paramount in wire mesh rolls factories. To ensure each roll meets industry standards, rigorous testing is conducted throughout the manufacturing process. This includes tensile strength tests, corrosion resistance tests, and visual inspections to identify any defects. Many factories adhere to international quality certifications, which not only assures customers of product quality but also enhances their reputation in the market.

Applications of Wire Mesh Rolls

Wire mesh rolls are utilized in a variety of sectors, demonstrating their adaptability and importance

- Construction In the construction industry, wire mesh is often used for reinforcement in concrete. It helps distribute loads and adds tensile strength, making structures more durable. - Agriculture Farmers use wire mesh rolls for fencing livestock, securing crops, and even as trellises for climbing plants. The durability and flexibility of wire mesh make it an invaluable asset in agricultural applications.

- Industrial Uses Many factories use wire mesh for filtration solutions, separating materials based on size and allowing for the movement of air or liquids without letting debris pass through.

- Home and Garden Homeowners often employ wire mesh for garden fencing, pet enclosures, and even decorative elements, enhancing the aesthetics of outdoor spaces.

Future Trends

As industries continuously evolve, so does the demand for wire mesh rolls. The push towards sustainable practices is leading manufacturers to explore eco-friendly materials and processes. Furthermore, advancements in manufacturing technologies, such as automation and enhanced weaving techniques, promise to enhance efficiency and reduce production costs.

Conclusion

Wire mesh rolls factories play a pivotal role in supplying this versatile product across various industries. With a thorough understanding of the manufacturing process and the quality control measures in place, businesses can trust that they are investing in a reliable and durable material. As demand evolves, these factories will continue innovating, ensuring that wire mesh remains an essential component in numerous applications.

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025