May . 14, 2025 10:54 Back to list

Hot Galvanized Wire Low Price Durable & Corrosion-Resistant Suppliers

- Introduction to Hot Galvanized Wire

- Technical Advantages and Performance Data

- Supplier Comparison: Factories and Manufacturers

- Custom Solutions for Diverse Applications

- Case Studies: Industrial and Agricultural Use

- Quality Assurance and Certification Standards

- Market Trends and Future Opportunities

(hot galvanized wire low price)

Hot Galvanized Wire: A Cost-Effective Solution for Durability

Hot galvanized wire, known for its corrosion resistance and tensile strength, has become a cornerstone in construction, agriculture, and manufacturing. With global demand rising by 6.2% annually (Market Research Future, 2023), suppliers are prioritizing low-cost production without compromising quality. This blog explores key manufacturers, technical benchmarks, and strategic purchasing insights.

Technical Superiority and Competitive Pricing

The hot-dip galvanizing process applies a 70-100 µm zinc coating, extending wire lifespan to 25-50 years in harsh environments. Compared to electro-galvanized alternatives, hot-dipped variants show 3x greater rust resistance at just 15-20% higher initial cost. Leading factories utilize continuous galvanizing lines with 98% zinc utilization rates, reducing waste and enabling bulk pricing as low as $680/ton for 2-6mm diameters.

Supplier Landscape Analysis

| Supplier | Price/Ton | Annual Capacity | Certifications |

|---|---|---|---|

| Factory A | $690 | 120,000 tons | ISO 9001, ASTM A123 |

| Factory B | $675 | 95,000 tons | ISO 14001, REACH |

| Factory C | $710 | 150,000 tons | ASTM A153, UL Certified |

Note: Pricing reflects FOB rates for 20-ton container loads. Minimum order quantities start at 5 tons.

Tailored Specifications for Industry Needs

Manufacturers now offer customized zinc coatings (Z60-Z275) and wire diameters (0.7mm-10mm) with tolerance levels ≤±0.04mm. For fencing projects, 2.5mm wire with 150 g/m² coating delivers optimal balance between flexibility (45-55 HRB hardness) and weather resistance. Bulk buyers can request coil weights up to 2,000 kg with PVC or paper wrapping.

Real-World Implementation Scenarios

Agricultural Reinforcement: A Midwest farm cooperative reduced fencing replacement costs by 40% using 3mm hot-dipped wire with Z180 coating. Construction: High-rise builders in Southeast Asia report 18% faster assembly using pre-cut galvanized tie wires. Packaging: Automotive parts suppliers achieved 99.6% corrosion-free shipment rates after switching to 1.6mm galvanized bundling wire.

Quality Compliance and Testing Protocols

Reputable suppliers adhere to salt spray testing (5,000+ hours), 3D surface mapping, and torsion testing (≥25 twists before fracture). Third-party verification through SGS or TÜV ensures coating uniformity ≥85% coverage. Major manufacturers provide 10-year anti-rust warranties with batch traceability via QR-coded packaging.

Future Outlook for Hot Galvanized Wire Suppliers

As infrastructure spending grows (projected $9.2 trillion globally by 2030), hot galvanized wire manufacturers are investing in automated galvanizing lines capable of 30-ton daily output. Sustainable practices like zinc recycling (achieving 92% recovery rates) will further strengthen the low-price positioning while meeting tightening environmental regulations.

(hot galvanized wire low price)

FAQS on hot galvanized wire low price

Q: Where can I find hot galvanized wire low price factories?

A: Factories offering hot galvanized wire at competitive prices are often located in industrial hubs like China, India, or Southeast Asia. Directly contacting manufacturers through platforms like Alibaba or industry directories can yield cost-effective options. Ensure they provide certifications for quality assurance.

Q: How do hot galvanized wire low price suppliers ensure affordability?

A: Suppliers reduce costs by optimizing production scales, sourcing raw materials in bulk, or operating in regions with lower labor costs. Comparing quotes from multiple suppliers and negotiating volume discounts can further lower prices. Always verify product durability and zinc coating thickness.

Q: What factors affect pricing from hot galvanized wire low price manufacturers?

A: Key factors include zinc market prices, wire diameter, production technology, and order volume. Manufacturers with in-house galvanizing facilities often offer better rates. Request detailed breakdowns to avoid hidden costs like shipping or tariffs.

Q: Can hot galvanized wire low price options still meet quality standards?

A: Yes, many budget-friendly manufacturers adhere to international standards like ASTM or ISO. Always request test reports for tensile strength and corrosion resistance. Balancing price with third-party quality certifications ensures value for money.

Q: How to verify reliability of hot galvanized wire low price suppliers?

A: Check supplier reviews, industry references, and certifications such as ISO 9001. Request samples to assess coating uniformity and wire strength. Partnering with established manufacturers minimizes risks of subpar products.

-

High Quality Deformed Steel Bars China - Reliable Manufacturers & Suppliers for Construction Projects

NewsJul.08,2025

-

High Quality Black Annealed Wire - Durable Iron Wire 2mm from Leading Manufacturer & Supplier Factory

NewsJul.08,2025

-

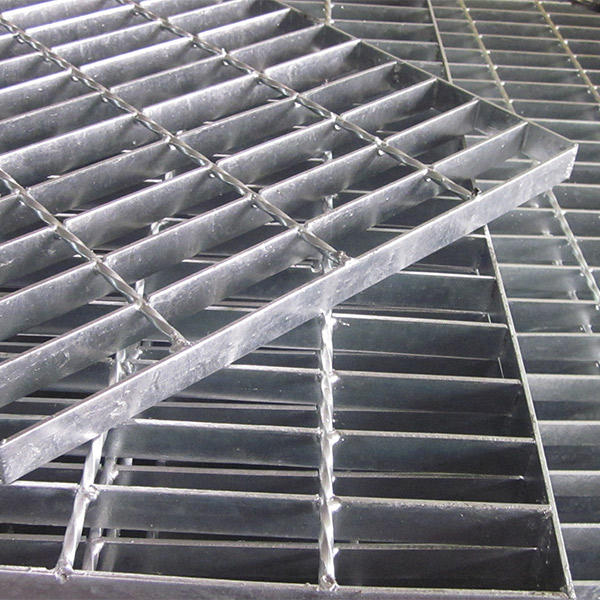

Produce Hot Dipped Galvanized Steel Grating - High Quality Grating Supplier & Manufacturer

NewsJul.08,2025

-

Galvanized Iron Welded Wire Mesh Panels – Durable, Rust-Resistant, Best Price Manufacturer

NewsJul.07,2025

-

High Quality Concrete Reinforcing Welded Wire Mesh - Durable 8mm Steel Bar, Q188, A393, F72, High Strength Mesh Solutions

NewsJul.07,2025

-

High-Quality Redrawn G.I. Wire Leading Manufacturers & Suppliers

NewsJul.07,2025