Okt . 13, 2024 11:29 Back to list

Reinforcement Mesh Solutions for Industrial Factory Construction and Safety Enhancements

The Importance of Reinforcing Mesh in Industrial Factories

In the realm of construction and manufacturing, the integrity and durability of structures are paramount. One key component that has become increasingly vital in industrial factories is reinforcing mesh. This essential element enhances the strength and stability of concrete, making it suitable for the demanding environments often found in industrial settings. Understanding the significance of reinforcing mesh not only aids in ensuring safety but also contributes to operational efficiency.

What is Reinforcing Mesh?

Reinforcing mesh, often made from steel wire, is designed to support concrete under tension. The mesh is composed of a grid of steel rods or wires, which are welded together to form a robust framework. This framework is then embedded within concrete to provide additional tensile strength, preventing cracking and enhancing the structural integrity of the poured material. The mesh can be used in various applications, from flooring and walls to foundations and larger structural elements.

Benefits of Using Reinforcing Mesh

1. Enhanced Strength and Durability One of the primary advantages of using reinforcing mesh is the significant increase in strength it provides to concrete structures. Industrial factories face various stresses, such as heavy machinery loads, vibrations, and thermal expansion. Reinforcing mesh distributes these loads evenly, minimizing the risk of structural failure.

2. Crack Resistance Concrete is susceptible to cracking due to tension forces, temperature changes, and settling. Incorporating reinforcing mesh helps to control these cracks, allowing for more extensive and controlled fissures to develop, which are less likely to compromise the structure's overall integrity. This feature is particularly important in industrial settings where seamless surfaces are often required for operations.

3. Cost-Effectiveness While there may be initial costs associated with acquiring and installing reinforcing mesh, it can lead to significant savings in the long run. Structures fortified with reinforcing mesh require less maintenance and, therefore, lower operational costs over time. Additionally, reducing the risk of structural damage means fewer costly downtimes and interruptions in production.

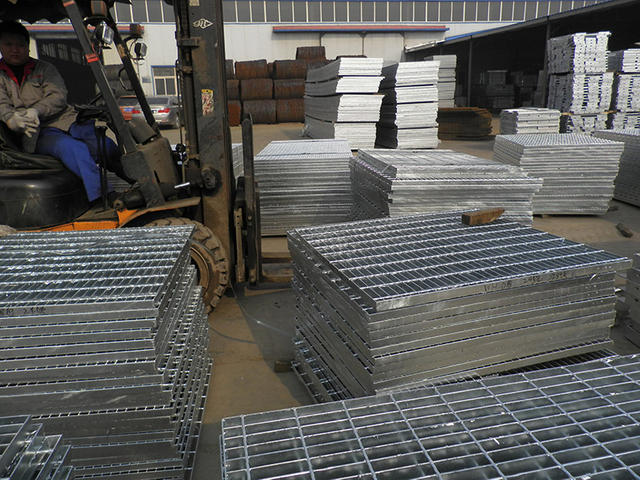

reinforcing mesh for industrial factories

4. Versatility Reinforcing mesh can be tailored to meet specific construction requirements. Different sizes, materials, and mesh configurations are available, allowing factories to select the most appropriate type for their unique applications. Whether it's for flooring that withstands heavy loads or walls that must resist lateral forces, there’s a suitable mesh available.

5. Ease of Installation Reinforcing mesh is relatively easy to install compared to other forms of reinforcement, such as rebar. This ease can lead to quicker construction times, which is crucial in the industrial sector where timing is often critical. With proper installation techniques, the mesh can be laid out and secured efficiently, expediting the concreting process.

Applications in Industrial Factories

Reinforcing mesh finds a wide range of applications in industrial factories. For instance, factory floors often endure significant wear and tear from the movement of heavy machinery and materials. A well-constructed concrete floor with reinforcing mesh minimizes the risk of cracks and prolongs the lifespan of the flooring system. Similarly, walls built using reinforcing mesh are often better able to withstand external forces, such as wind loads and vibrations from equipment.

Furthermore, reinforcing mesh is also employed in precast products, which are commonly used in constructing industrial buildings. By incorporating mesh into these components, manufacturers can ensure that their structures are built to withstand the rigorous demands of industrial use.

Conclusion

In summary, reinforcing mesh serves as an indispensable asset in the construction and maintenance of industrial factories. Its ability to enhance strength, resist cracking, and provide cost-effective solutions makes it a critical component in modern industrial architecture. As factories continue to evolve and embrace larger-scale operations, the importance of utilizing reinforcement methods like mesh will only increase, ensuring safe, efficient, and durable industrial environments. In a sector where structural integrity directly correlates with productivity, reinforcing mesh stands out as a key player in bolstering factory resilience.

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025