Dis . 04, 2024 09:05 Back to list

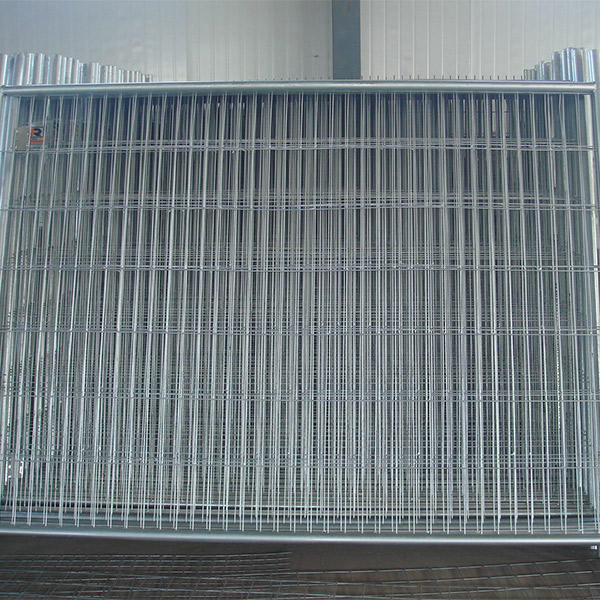

high strength wire factory

High Strength Wire Factory A Backbone of Modern Industries

In the ever-evolving landscape of technology and manufacturing, the significance of high strength wire cannot be overstated. These wires are pivotal in numerous applications, from construction and automotive to aerospace and telecommunications. A high strength wire factory plays a crucial role, supplying the essential materials that enable industries to thrive and innovate. This article delves into the operations, significance, and advancements within a typical high strength wire factory.

Understanding High Strength Wire

High strength wire is engineered to endure extreme conditions, making it suitable for applications that require enhanced durability and reliability. Typically made from materials such as steel or specialized alloys, high strength wires exhibit superior tensile strength and resistance to fatigue. They are commonly used in situations where traditional wires may fail, such as suspension bridges, cranes, cables for elevators, and reinforced concrete structures.

The Operations of a High Strength Wire Factory

A high strength wire factory encompasses a series of intricate processes aimed at producing wires that meet stringent specifications. The production process begins with raw material selection, where steel or other alloys are sourced based on desired mechanical properties. This is followed by processes such as wire drawing, annealing, and coating.

1. Wire Drawing In this initial stage, the raw materials are drawn through a series of dies to reduce their diameter. Wire drawing not only shapes the wire but also increases its strength through work hardening.

2. Annealing After drawing, the wires undergo an annealing process. This step is critical for relieving stresses induced during drawing, allowing the wire to achieve optimal ductility and toughness without compromising its strength.

3. Coating To enhance corrosion resistance and extend the lifespan of high strength wires, coatings such as zinc or polymer are applied. This step also ensures compatibility with various applications, especially in outdoor or corrosive environments.

4. Quality Control Rigorous quality control is paramount in a high strength wire factory. Each batch of wire undergoes comprehensive testing to ascertain its mechanical properties, including tensile strength, elongation, and fatigue resistance. Non-destructive testing techniques, such as ultrasonic and magnetic particle inspections, are employed to identify any defects.

high strength wire factory

Significance in Various Industries

The importance of high strength wire extends across multiple sectors. In the construction industry, for example, these wires are vital components of reinforcing bars and cables that support large structures such as bridges and skyscrapers. They ensure safety and structural integrity under heavy loads and adverse conditions.

In the automotive sector, high strength wires are utilized in manufacturing components like suspension systems and safety features. Their lightweight yet robust nature contributes to overall vehicle performance and efficiency.

The aerospace industry relies heavily on high strength wires for applications in aircraft manufacturing and satellite deployment systems. These wires are essential for maintaining structural integrity while minimizing weight, contributing to fuel efficiency and performance.

Innovations Transforming the Industry

Advancements in technology are continuously transforming high strength wire manufacturing. With the adoption of automation and Industry 4.0 principles, factories are becoming more efficient and responsive to market demands. Smart manufacturing techniques, including IoT-enabled monitoring systems, enhance production efficiency and quality control.

Moreover, ongoing research into new materials and alloys is paving the way for the development of even stronger and lighter wires. Innovations such as nanotechnology and advanced composite materials are expected to revolutionize the properties of high strength wires, expanding their applications even further.

Conclusion

A high strength wire factory stands as a testament to the intricate interplay between manufacturing prowess and technological advancements. By supplying critical materials that enhance safety and performance across various industries, these factories contribute significantly to modern infrastructure and innovation. As technology continues to evolve, so too will the capabilities of high strength wire manufacturing, ensuring its position as a cornerstone of progress in the industrial landscape. The future promises not only stronger and more efficient wires but also a plethora of new applications that will shape the industries of tomorrow.

-

Premium Welded Reinforcing Mesh SL62/SL72/SL82 High-Strength Solutions

NewsJun.01,2025

-

Diamond Mesh Expanded Sheet Factories Durable & High-Strength Design

NewsJun.01,2025

-

REO Mesh Solutions High-Quality Manufacturers & Trusted Suppliers

NewsJun.01,2025

-

SL72 Reinforcing Fabric Factories & Suppliers High-Strength Material

NewsMay.31,2025

-

Electro Galvanized Wire Low Price Durable & Affordable Suppliers

NewsMay.31,2025

-

Steel Driveway Grates Grating - Heavy-Duty & Custom Sizes

NewsMay.31,2025