Nov . 14, 2024 10:32 Back to list

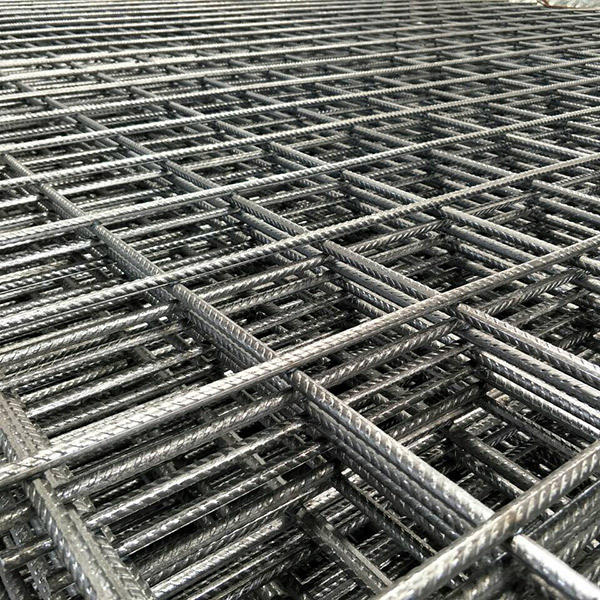

china welding steel mesh

The Evolution and Significance of Steel Mesh Welding in China

In recent years, the steel industry in China has experienced unprecedented growth, driven by the country's rapid urbanization and infrastructural development. Among the myriad of products produced in this sector, welded steel mesh stands out as a crucial component for construction and engineering projects. This article explores the evolution, manufacturing processes, applications, and the importance of welded steel mesh in China.

Evolution of Steel Mesh Welding in China

The practice of welding steel mesh in China dates back several decades, gaining traction in the late 20th century as construction methods evolved. Earlier, construction relied heavily on traditional reinforcement techniques, which often resulted in inconsistencies and inefficiencies. The introduction of welded steel mesh revolutionized the construction process, allowing for more uniform strength and reduced labor costs.

As China embraced modernization and industrialization, the demand for more robust and reliable construction materials surged. Government policies aimed at improving building standards and safety also played a significant role in driving the production of high-quality welded steel mesh. Today, China stands as one of the largest producers of welded steel mesh in the world, exporting to various countries and contributing significantly to global construction endeavors.

Manufacturing Process

The production of welded steel mesh involves several steps, from wire drawing to welding and finishing. The process typically begins with the selection of high-quality steel wire, which is then drawn into the desired diameter. This wire is subsequently arranged in a grid pattern, where cross wires are placed at specified intervals.

The grid is then subjected to a welding process, where electrical currents are applied to fuse the wires at their intersections. This method ensures a strong bond, creating a stable and durable mesh. After welding, the mesh is usually treated with anti-corrosion coatings or galvanization to enhance its longevity and performance in various environmental conditions.

The automation of the welding process has significantly increased production efficiency, allowing manufacturers to meet the high demands of the construction industry without compromising quality. Strict quality control measures are also implemented throughout the manufacturing process to ensure that the final products adhere to the relevant industry standards and regulations.

china welding steel mesh

Applications of Steel Mesh Welding

Welded steel mesh has a wide range of applications in construction and engineering. It is commonly used as reinforcement in concrete slabs, beams, walls, and foundations. The mesh enhances load distribution, reduces cracking, and increases the overall structural integrity of the building.

In addition to traditional construction, welded steel mesh is also utilized in various specialized applications, such as in the production of precast concrete products, road construction, and even in landscaping projects. Its versatility makes it an essential material in diverse sectors, including residential, commercial, and industrial construction.

Moreover, welded steel mesh plays a vital role in ensuring safety and stability in infrastructure projects. For instance, in bridge construction, the mesh is integrated into concrete to provide additional support and resistance to tensile forces, ensuring that structures can withstand heavy loads and extreme weather conditions.

The Importance of Welded Steel Mesh in China

The significance of welded steel mesh in China's construction industry cannot be overstated. As the country continues to urbanize at a rapid pace, the demand for safe and efficient construction materials is more pertinent than ever. Welded steel mesh not only meets this demand but also contributes to sustainable building practices by optimizing material use and reducing waste.

Furthermore, the production and use of welded steel mesh bolster China's economy by creating jobs and fostering technological advancements in the manufacturing sector. As companies invest in research and development, the quality and efficiency of welded steel mesh production continue to improve.

In conclusion, welded steel mesh represents a pivotal advancement in construction technology in China. Its evolution from a basic reinforcement method to a sophisticated product illustrates the country’s commitment to modernization and quality in construction. As China continues to grow and develop, welded steel mesh will undoubtedly remain a cornerstone of its building industry, enhancing the safety, efficiency, and sustainability of infrastructure projects nationwide.

-

Industrial-Grade Welded Wire Mesh for Factories & Suppliers | Durable

NewsJul.25,2025

-

Precision Cold Drawn Wire: High Strength & Durability Solutions

NewsJul.25,2025

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen|Durable Security Solution&Cost-Effective Fencing

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsJul.21,2025

-

Galvanized Steel Chain Link Fences-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable Corrosion-Resistant Fencing&Cost-Effective Security Solutions

NewsJul.21,2025