nov. . 15, 2024 20:31 Back to list

1mm galvanized iron wire factory

Understanding 1mm Galvanized Iron Wire Factories

In today's industrial landscape, galvanized iron wire serves a multitude of applications, from construction to fencing. The significance of manufacturers specializing in 1mm galvanized iron wire cannot be overstated, as they contribute to a wide range of sectors that depend on durability and strength in their materials. This article explores the production processes, benefits, and applications of 1mm galvanized iron wire, shedding light on why factories specializing in this sector are pivotal.

What is Galvanized Iron Wire?

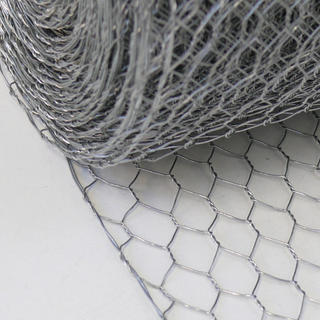

Galvanized iron wire is iron wire that has been coated with a layer of zinc to prevent rust and corrosion. The galvanization process involves either hot-dipping or electroplating the iron wire, which not only enhances its lifespan but also improves its surface quality. This coating makes galvanized iron wire an ideal choice for various outdoor applications where exposure to moisture is a concern.

The Importance of the 1mm Diameter

The 1mm diameter of galvanized iron wire is particularly popular among manufacturers and consumers due to its versatility. It strikes a balance between strength and flexibility, making it suitable for a range of applications. Whether used in construction reinforcement, crafting, or fencing, 1mm galvanized iron wire proves to be reliable and efficient. Its ability to withstand tension while remaining relatively lightweight makes it a favored choice for many industries.

Production Processes in Factories

Factories producing 1mm galvanized iron wire utilize advanced technology and skilled expertise to ensure high-quality output. The production process typically begins with high-grade steel wire, which is drawn down to the desired diameter of 1mm. Following this, the wire undergoes the galvanization process – often hot-dipping – where it is submerged in molten zinc. This method ensures a thicker and more durable coating compared to electroplating.

1mm galvanized iron wire factory

Quality control is critical in galvanized iron wire factories. Consistent monitoring during production helps maintain the quality of the wire, ensuring it meets industry standards for tensile strength and corrosion resistance. Many factories also invest in modern machinery that increases production efficiency while reducing waste, resulting in a more sustainable operation.

Applications of 1mm Galvanized Iron Wire

1mm galvanized iron wire finds use in a plethora of applications. In the construction industry, it is frequently employed for tying rebar together, providing additional strength to concrete structures. Moreover, it is widely used in the agricultural sector for fencing, as it creates robust barriers that are resistant to harsh weather conditions and pests.

Beyond construction and agriculture, 1mm galvanized iron wire is also popular in the crafting and DIY sectors. Hobbyists utilize this wire for making sculptures, jewelry, and various art projects. Its malleability allows for a range of creative applications, making it a favorite among artists and DIY enthusiasts alike.

Environmental Considerations

As industries become increasingly aware of their environmental impact, galvanized iron wire factories are adapting by implementing eco-friendly practices. Many factories now prioritize using recycled materials and employ energy-efficient methods to minimize their carbon footprint. This shift not only benefits the environment but also appeals to consumers who are increasingly demanding sustainable products.

Conclusion

In conclusion, 1mm galvanized iron wire factories play a crucial role in manufacturing a product that serves diverse industrial needs. Through advanced production techniques and rigorous quality control, these factories ensure the delivery of robust and durable wire that meets the demands of various applications. As industries continue to evolve, the importance of reliable materials like 1mm galvanized iron wire will undoubtedly grow, solidifying its place in the market.

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.23,2025

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen|Durable Security Solution&Cost-Effective Fencing

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsJul.21,2025

-

Galvanized Steel Chain Link Fences-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable Corrosion-Resistant Fencing&Cost-Effective Security Solutions

NewsJul.21,2025

-

Diamond Steel Grating - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable Industrial Solutions&Customized Steel Grating

NewsJul.21,2025