nov . 20, 2024 21:01 Back to list

welded mesh for bridge factories

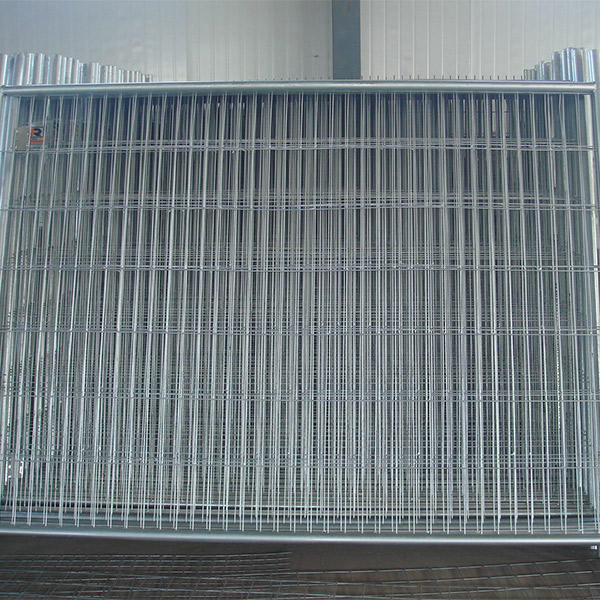

Welded Mesh for Bridge Factories An Overview

The construction of bridges is a complex process that demands precision, durability, and safety. Among the various materials and technologies involved in bridge construction, welded mesh has emerged as a vital component. This article delves into the significance of welded mesh in bridge factories, highlighting its benefits, applications, and the role it plays in ensuring structural integrity.

Understanding Welded Mesh

Welded mesh, often referred to as welded wire mesh, consists of a grid of wires that are electrically welded together at their intersections. This grid is produced in different sizes and specifications to cater to various construction needs. The primary materials used to fabricate welded mesh include high-tensile steel, which provides enhanced strength and durability, making it suitable for heavy-load applications such as bridges.

Importance in Bridge Construction

1. Strength and Stability One of the primary reasons for using welded mesh in bridge construction is its ability to evenly distribute loads across the structure. Bridges are subjected to various forces, including vehicular traffic, wind pressure, and seismic activity. The welded mesh framework helps in mitigating these stresses, ensuring the stability of the bridge over time.

2. Corrosion Resistance Bridges are often exposed to harsh environmental conditions, including moisture, salt, and extreme temperature variations. Manufacturers can treat welded mesh to enhance its corrosion resistance, extending its lifespan and reducing maintenance costs.

3. Cost-Effectiveness Utilizing welded mesh in bridge construction can lead to significant cost savings. The ease of installation reduces labor costs, while its durability minimizes the need for frequent repairs or replacements. Consequently, project managers can allocate resources more efficiently, ensuring that projects are completed within budget constraints.

4. Versatility Welded mesh can be used in various forms within bridge construction, including in deck reinforcement, barrier systems, and support structures. Its versatility makes it an essential material for different types of bridges, whether they are pedestrian walkways, vehicular overpasses, or complex multi-span structures.

Applications of Welded Mesh in Bridge Factories

welded mesh for bridge factories

In bridge factories, welded mesh can be employed in several critical applications

- Reinforcement for Concrete Elements Concrete is a primary material in bridge construction. By integrating welded mesh within concrete elements, engineers can significantly enhance tensile strength, preventing cracks and structural failure.

- Temporary Structures During the construction phase, welded mesh can serve as a temporary support structure to hold forms in place, ensuring that concrete sets properly without undue stress.

- Safety Barriers To ensure the safety of both vehicles and pedestrians, welded mesh can be utilized in the form of safety barriers and guardrails. This application not only provides protection but also adds to the aesthetic appeal of the bridge.

Quality Control in Welded Mesh Manufacturing

To ensure the reliability of welded mesh used in bridge construction, strict quality control measures are necessary. Manufacturers must adhere to international standards and regulations that govern materials used in structural applications. Regular testing of tensile strength, weld integrity, and corrosion resistance is essential to maintain high-quality production.

Moreover, advancements in technology have led to improved manufacturing processes. Automated welding techniques and precision machinery allow for the production of consistent and high-quality welded mesh, meeting the rigorous demands of bridge construction.

Conclusion

Welded mesh is an integral material in the realm of bridge factories, playing a crucial role in ensuring the safety, durability, and efficiency of bridge construction projects. Its strength, versatility, and cost-effectiveness make it a preferred choice for engineers and contractors alike. As the industry continues to evolve, the use of welded mesh is likely to expand, paving the way for safer and more efficient bridge designs. With ongoing advancements in manufacturing techniques and materials science, the future of welded mesh in bridge construction looks promising, holding the potential for innovation in infrastructure development.

-

Premium Fly Wire Netting – Durable Insect Screens, UV-Resistant

NewsJun.06,2025

-

GI Welded Wire Mesh Fence Heavy-Duty & Corrosion Resistant

NewsJun.06,2025

-

Premium Gabion Welded Wire Mesh High-Strength & Corrosion-Resistant

NewsJun.06,2025

-

Premium Concrete Reinforcing Mesh Direct from Chinese Suppliers

NewsJun.06,2025

-

Premium Black Nail Wire Suppliers - Durable & Corrosion Resistant

NewsJun.06,2025

-

Steel Fence Posts & Railing Designs Premium Metal Fencing Solutions

NewsJun.05,2025