dec . 18, 2024 17:57 Back to list

fence wire mesh panels factories

Exploring the World of Fence Wire Mesh Panels Factories

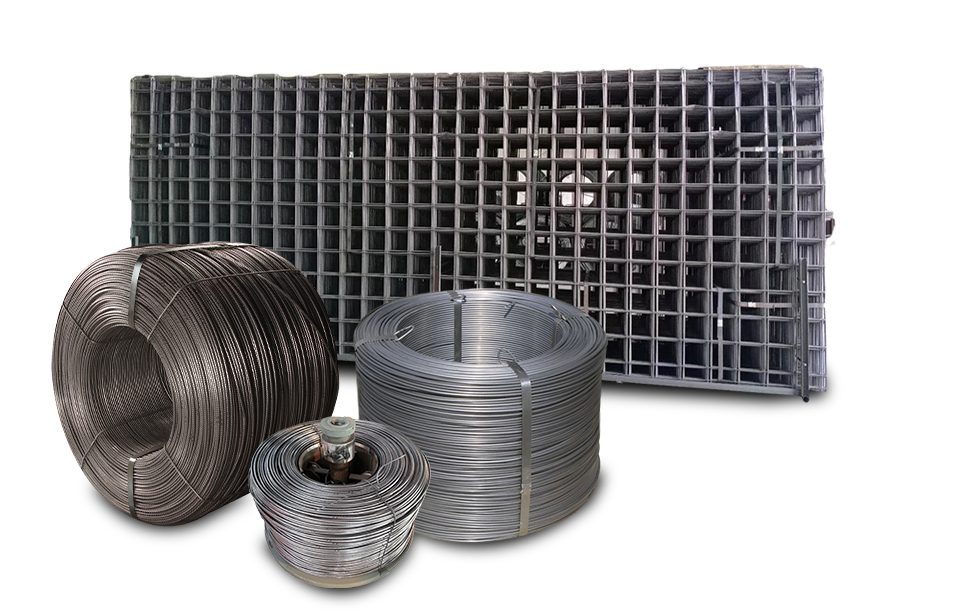

In today's rapidly evolving construction and agricultural industries, the demand for durable and versatile fencing solutions has never been higher. Among the various options available, wire mesh panels have emerged as a preferred choice due to their adaptability, strength, and cost-effectiveness. This article delves into the realm of fence wire mesh panel factories, exploring their significance, manufacturing processes, and the broad applications of these essential products.

Understanding Wire Mesh Panels

Wire mesh panels are constructed from woven or welded wires that create a grid-like structure. This design provides structural integrity while maintaining visibility and air passage. These panels come in various sizes, wire gauges, and finishes, making them suitable for a multitude of applications, including agricultural enclosures, security fencing, and landscaping projects. The choice of materials, often galvanized or coated with PVC, enhances their durability and resistance to corrosion, ensuring a long lifespan even in harsh weather conditions.

The Role of Fence Wire Mesh Panel Factories

The factories that produce wire mesh panels play a crucial role in meeting the rising demand from various sectors. These facilities are equipped with specialized machinery that enables efficient manufacturing processes, from wire drawing to welding and finishing. The primary components involved in the production of wire mesh panels include

1. Wire Production The first step in the manufacturing process is the creation of wire from raw materials, typically steel. This wire must undergo multiple processes, including drawing, which reduces its diameter to the desired gauge, followed by surface treatment to enhance corrosion resistance.

2. Mesh Formation Once the wire has been produced, it is either woven or welded to form the mesh. Woven wire mesh uses interlocking wires, while welded wire mesh involves fusing wire intersections together, resulting in a more robust structure.

3. Cutting and Finishing After the mesh has been formed, panels are cut to specific sizes as per customer requirements. Post-cutting, the panels are finished with protective coatings, such as galvanization or painting, to ensure longevity and aesthetic appeal.

4. Quality Control A critical aspect of production is quality control. Factories implement stringent quality checks throughout the manufacturing process to ensure that the panels meet industry standards and customer expectations. This includes testing for strength, corrosion resistance, and overall durability.

fence wire mesh panels factories

Applications of Wire Mesh Panels

The versatility of wire mesh panels allows for their use in a wide range of applications

- Agricultural Fencing Farmers increasingly utilize wire mesh panels to protect crops and livestock. These panels serve as enclosures that deter predators while still allowing farmers to monitor their fields easily.

- Security Fencing Industrial and commercial properties often utilize wire mesh panels as a security measure. Their strength and visibility enable effective surveillance while preventing unauthorized access.

- Landscape and Garden Fencing Homeowners frequently turn to wire mesh panels for decorative garden fencing or as tree protectors. They can be integrated with other materials for aesthetic purposes while remaining functional.

- Construction Sites To safeguard construction zones, temporary wire mesh fencing is commonly used. It’s portable and easy to install, providing a quick solution for site security.

Choosing the Right Factory

Selecting a reliable wire mesh panel factory is vital for obtaining high-quality products. Factors to consider include the factory’s reputation in the industry, the materials used, customization options, and overall production capabilities. Sustainable practices, such as utilizing recycled materials or eco-friendly processes, are also becoming increasingly important for businesses conscious of their environmental impact.

Conclusion

In conclusion, fence wire mesh panel factories are integral to providing an essential product that finds its applications in various sectors. As industries continue to evolve and the demand for effective fencing solutions grows, these factories are poised to innovate and adapt to changing market needs. By understanding the manufacturing processes and applications, consumers can make informed decisions when selecting wire mesh panels for their specific requirements, contributing to the continued success and relevance of this vital industry.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025