নভে. . 22, 2024 00:49 Back to list

welded mesh for bridge manufacturers

The Importance of Welded Mesh for Bridge Manufacturers

In the world of civil engineering, the reliability and strength of construction materials are crucial for ensuring the safety and longevity of structures. Among these materials, welded mesh has become an integral element in the construction of bridges. This product, well-regarded for its durability and versatility, offers numerous advantages that bridge manufacturers cannot afford to overlook.

Understanding Welded Mesh

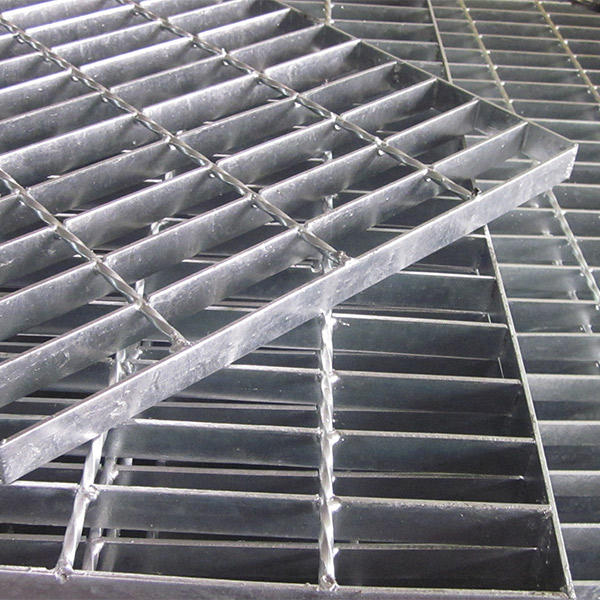

Welded mesh, often made from high-quality steel wires, is created by welding the intersections of the wires together, forming a grid pattern. This connection results in a robust and stable structure, which can withstand various forms of stress, including tension and compression. The welded mesh can be produced in various thicknesses and sizes, allowing for tailored solutions that meet specific engineering requirements.

Benefits of Welded Mesh in Bridge Construction

1. Strength and Durability One of the primary reasons welded mesh is favored in bridge construction is its inherent strength. The welding process creates a continuous mesh that maintains integrity even when subjected to heavy loads and environmental factors. Bridges, being significant structures that must endure vehicular traffic and natural elements such as wind or seismic activity, benefit substantially from this characteristic.

2. Cost-Effectiveness When considering construction costs, welded mesh offers an economical solution. Its production can be streamlined to reduce waste, and the material itself is often less expensive than other reinforcement methods. Furthermore, the speed of installation can lead to significant labor savings, making it a practical choice for large-scale projects.

3. Versatility Welded mesh can be utilized in various applications, making it suitable for different types of bridges—from pedestrian walkways to large vehicle bridges. The flexibility in design and the ability to customize mesh sizes according to project specifications provide engineers with more options in their structural designs.

4. Enhanced Safety The use of welded mesh increases the overall safety of bridge structures. By providing a reliable reinforcement method, the risk of failure can be minimized, ensuring that bridges remain safe for public use. Additionally, welded mesh helps distribute loads evenly across the structure, which can mitigate potential stress points.

welded mesh for bridge manufacturers

5. Resistance to Corrosion Many manufacturers offer welded mesh that is treated to resist corrosion, which is particularly important for bridges exposed to moisture, chemicals, and varying weather conditions. Stainless steel options are available, further enhancing the lifespan and reducing maintenance costs for bridge structures.

Innovations in Welded Mesh Technology

As technology advances, so do the applications and manufacturing processes for welded mesh. Innovations such as automated welding machines and advanced steel processing techniques have improved the quality and precision of welded mesh products. These advancements facilitate the production of high-tensile welded mesh solutions that meet the demands of modern engineering.

Moreover, sustainable practices in manufacturing welded mesh are gaining traction. By utilizing recycled materials and implementing energy-efficient production methods, manufacturers can contribute to environmentally friendly construction practices that are increasingly important in today’s industry.

The Future of Welded Mesh in the Bridge Sector

Looking ahead, the demand for welded mesh in the bridge manufacturing sector is expected to grow as infrastructure projects expand globally. The ongoing need for durable and cost-effective materials in bridge construction will likely keep welded mesh at the forefront of engineers' and architects' choices.

With the push for innovation and sustainability, combined with the inherent advantages of welded mesh, it remains a top contender for future bridge projects. For manufacturers, staying abreast of these developments, as well as understanding the specific requirements of various projects, is essential for harnessing the full potential of welded mesh in bridge construction.

Conclusion

In summary, welded mesh represents a vital component in the structural integrity and efficiency of bridge construction. Its benefits—strength, cost-effectiveness, versatility, safety, and resistance to corrosion—solidify its position as a preferred choice among bridge manufacturers. As the industry continues to innovate and seek sustainable solutions, welded mesh will undoubtedly play a significant role in the future of infrastructure development.

-

Premium Binding Iron Wire High Strength & Durable Solutions

NewsJun.03,2025

-

Durable Galvanized Metal Wire for Construction Anti-Corrosion

NewsJun.03,2025

-

Diamond Mesh Fence Wire Fencing Durable & Versatile Solutions Galvanized Options

NewsJun.03,2025

-

12mm Stainless Steel Wire Mesh Durable, Corrosion-Resistant Suppliers

NewsJun.03,2025

-

Premium Black Binding Wire High-Strength & Corrosion-Resistant Solutions

NewsJun.02,2025

-

High Strength Wire & A393 Q188 Reinforcing Mesh 8mm Steel Bar Suppliers

NewsJun.02,2025