сеп. . 18, 2024 23:31 Back to list

welded mesh for bridge factories

Welded Mesh for Bridge Factories An Essential Component in Modern Construction

In contemporary construction, particularly in the field of civil engineering, the significance of welded mesh cannot be overstated. Specifically, in bridge factories, where structural integrity and durability are paramount, welded mesh plays a crucial role in enhancing the strength and stability of bridge constructions. This article delves into the applications, benefits, and considerations associated with the use of welded mesh in bridge manufacturing.

Understanding Welded Mesh

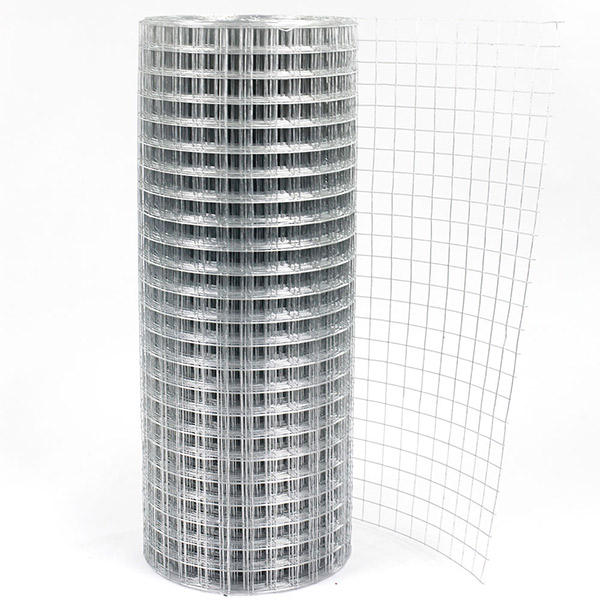

Welded mesh is a grid-like structure made from high-strength steel wires that are welded at their intersections. This method of construction results in a material that is not only robust but also versatile, making it suitable for various applications in bridge construction. Its introduction into the construction industry has revolutionized how engineers and architects approach the design and implementation of structural frameworks.

Applications in Bridge Construction

In bridge factories, welded mesh is primarily utilized in the reinforcement of concrete structures. When combined with concrete, welded mesh helps to distribute loads evenly, thus reducing the likelihood of structural failure. This reinforcement is vital in areas where high tensile strength is required, such as in beams, slabs, and other load-bearing components of a bridge.

Moreover, welded mesh is employed in the construction of bridge decks. The grid structure effectively supports the weight of vehicles and pedestrians, ensuring safety and stability. Additionally, its use is not limited to new constructions; welded mesh can also be incorporated into the rehabilitation of existing bridges, providing enhanced support and extending their lifespan.

Benefits of Welded Mesh

welded mesh for bridge factories

The advantages of using welded mesh in bridge factories are numerous. Firstly, it offers superior strength compared to traditional reinforcement methods, thereby improving the overall durability of the structure. This strength is particularly beneficial in regions susceptible to harsh environmental conditions, such as high winds, heavy rainfall, or seismic activities.

Secondly, welded mesh facilitates quicker construction times. As it is manufactured in standardized sizes and shapes, it can be easily transported and installed on-site, reducing the time required for assembly. This efficiency translates into cost savings for construction projects, allowing for better allocation of resources and potentially lower overall expenses.

Additionally, the precision of welded mesh ensures a consistent quality throughout the reinforced areas. This uniformity is critical for maintaining structural integrity and meeting the stringent safety regulations required in bridge construction.

Considerations in Usage

While welded mesh offers numerous benefits, there are considerations that engineers must account for when integrating it into bridge designs. The selection of appropriate wire diameters and spacing is crucial, as it directly impacts the load-carrying capacity of the structure. Furthermore, ensuring resistance to corrosion is vital, especially in environments exposed to moisture and de-icing chemicals.

Moreover, the design must account for the potential fatigue of welded joints, which can be a concern in high-load scenarios. Choosing the right specifications based on the expected live loads and environmental conditions will determine the long-term performance of the welded mesh in a bridge.

Conclusion

In summary, welded mesh is a fundamental element in the construction of bridges. Its unparalleled strength, efficiency in installation, and ability to enhance the structural integrity of bridges make it an invaluable asset in bridge factories. As the demand for durable and cost-effective construction materials continues to grow, welded mesh is likely to play an increasingly prominent role in shaping the future of bridge engineering.

-

High Quality Deformed Steel Bars China - Reliable Manufacturers & Suppliers for Construction Projects

NewsJul.08,2025

-

High Quality Black Annealed Wire - Durable Iron Wire 2mm from Leading Manufacturer & Supplier Factory

NewsJul.08,2025

-

Produce Hot Dipped Galvanized Steel Grating - High Quality Grating Supplier & Manufacturer

NewsJul.08,2025

-

Galvanized Iron Welded Wire Mesh Panels – Durable, Rust-Resistant, Best Price Manufacturer

NewsJul.07,2025

-

High Quality Concrete Reinforcing Welded Wire Mesh - Durable 8mm Steel Bar, Q188, A393, F72, High Strength Mesh Solutions

NewsJul.07,2025

-

High-Quality Redrawn G.I. Wire Leading Manufacturers & Suppliers

NewsJul.07,2025