снеж . 06, 2024 21:24 Back to list

sl72 welded wire mesh factory

The Advantages of SL72% Welded Wire Mesh A Comprehensive Overview of the Factory Process

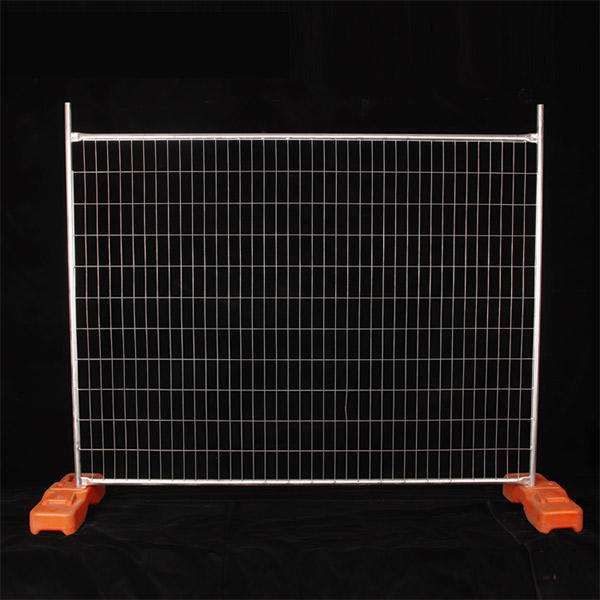

In the realm of construction and fencing, SL72% welded wire mesh has emerged as a go-to material for both professional builders and DIY enthusiasts. Its versatility, strength, and ease of installation make it an invaluable asset in various applications, ranging from foundations to agricultural uses. This article explores the manufacturing process of SL72% welded wire mesh, its benefits, and the reasons behind its increasing popularity in the construction industry.

What is SL72% Welded Wire Mesh?

SL72% welded wire mesh is a type of fencing material composed of intersecting wires welded together at each junction. The designation SL72% refers to the specific grid pattern of the mesh and the space it covers. The mesh typically features a square or rectangular design, providing even spacing between wires, which contributes to its strength and stability. This type of wire mesh is generally made from high-quality steel, which is treated to withstand various environmental conditions, making it suitable for both indoor and outdoor applications.

Manufacturing Process

The production of SL72% welded wire mesh involves several key steps, ensuring that the final product meets high standards of durability and reliability.

1. Raw Material Selection The process begins with the selection of high-grade steel wire. The quality of the raw material is crucial as it affects the mesh's overall strength and resistance to corrosion.

2. Wire Preparation Once the steel wire is sourced, it undergoes a treatment process that may include galvanization. Galvanization involves coating the wire with a layer of zinc to protect it from rust and extend its lifespan. Depending on the intended use, manufacturers may choose different coating thicknesses.

4. Welding Process The cut wires are arranged in the specified grid pattern. Automated welding machines then weld the intersections of the wires, creating a solid structure. This welding process ensures that each joint is robust, preventing dislocations and providing a stable mesh system.

5. Quality Control After the welding stage, the mesh undergoes a rigorous quality control procedure. This involves checking for any inconsistencies, defects, or weak spots in the structure. Only products that meet specific standards are approved for distribution.

sl72 welded wire mesh factory

6. Packaging and Shipping Once the mesh passes quality control, it is cleaned, packaged, and prepared for shipping. Manufacturers often provide options for different roll sizes or sheets, catering to the varying needs of customers.

Benefits of SL72% Welded Wire Mesh

SL72% welded wire mesh offers several advantages that make it a superior choice for many applications

- Strength and Durability The welding process significantly enhances the strength of the wire mesh, making it resistant to bending, breaking, and deformation under pressure.

- Corrosion Resistance When appropriately galvanized, SL72% welded wire mesh resists corrosion and rust, allowing it to maintain its integrity when exposed to moisture and other environmental elements.

- Versatility This type of mesh can be utilized in numerous applications, including construction foundations, animal enclosures, landscaping, and creating partitions. Its versatile nature makes it suitable for both residential and commercial projects.

- Cost-Effective When compared to other fencing materials, SL72% welded wire mesh presents a cost-effective solution, as it requires minimal maintenance and lasts for many years.

- Ease of Installation With its lightweight design and uniform dimensions, SL72% welded wire mesh can be easily installed. This feature is particularly advantageous for those undertaking DIY projects.

Conclusion

As the demand for durable and cost-effective materials continues to grow in the construction industry, SL72% welded wire mesh stands out as a reliable option. The meticulous manufacturing process, combined with its numerous benefits, makes it an essential product for a wide range of applications. Whether you are a contractor, a farmer, or a homeowner, incorporating SL72% welded wire mesh into your projects can lead to lasting quality and satisfaction. Investing in this versatile material not only ensures strength and reliability but also contributes to the overall success of your construction endeavors. As production techniques continue to advance, SL72% welded wire mesh will undoubtedly remain a staple in the industry for years to come.

-

Best Price Black Annealed Wire Manufacturer Direct Sale Factories

NewsMay.17,2025

-

Galvanized Welded Iron Wire Mesh Durable & Rust-Resistant Panels

NewsMay.17,2025

-

High-Strength Binding Iron Wire Suppliers & Manufacturers Custom Solutions

NewsMay.16,2025

-

BWG22 Galvanized Welded Wire Mesh 30m Roll Durable & Corrosion-Resistant

NewsMay.16,2025

-

REO Mesh Solutions High-Quality, Durable & Customizable Wire Mesh

NewsMay.16,2025

-

12 Gauge Welded Wire Mesh Supplier Heavy-Duty Galvanized Factory

NewsMay.15,2025