ጥቅም . 30, 2024 18:49 Back to list

reinforcing mesh a393 factory

Understanding A393 Reinforcing Mesh A Comprehensive Guide

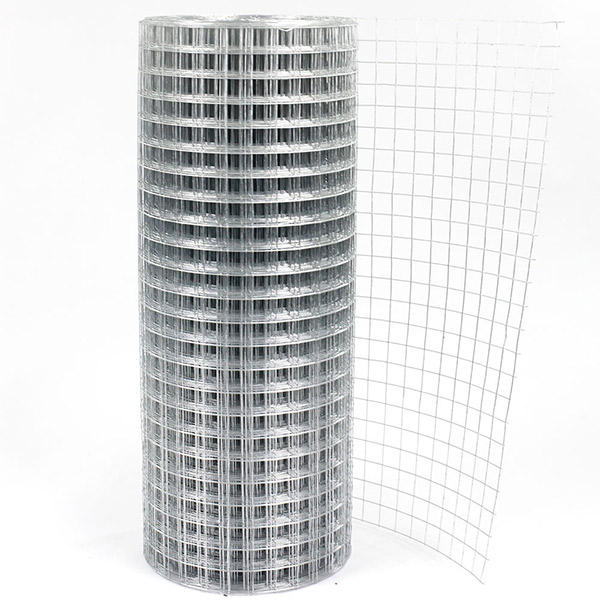

Reinforcing mesh, commonly referred to as rebar mesh or welded wire mesh, is widely used in the construction industry to enhance the strength and durability of concrete structures. Among the various types of reinforcing mesh available, A393 mesh stands out due to its specific characteristics and applications. This article will explore the features, manufacturing process, applications, and advantages of A393 reinforcing mesh.

Features of A393 Reinforcing Mesh

A393 reinforcing mesh is characterized by its wire diameter and spacing. Typically, it consists of high-quality steel wires with a nominal diameter of 10 mm (or 0.4 inches). The mesh is designed with a 200 mm x 200 mm spacing pattern. This configuration provides significant structural support, making it ideal for various construction projects. The A393 mesh is recognized for its robust tensile strength, which is essential for absorbing stresses and preventing cracking in concrete.

Manufacturing Process

The manufacturing process of A393 reinforcing mesh involves several critical steps. Initially, high-grade steel wires are sourced and cut to the desired lengths. These wires are then arranged in a grid pattern, adhering to the stipulated spacing. The wires are welded at their intersections using advanced techniques that ensure structural integrity and durability. The welded mesh is often coated with anti-corrosive materials to enhance its longevity, especially in environments prone to moisture and other corrosive elements.

Applications

reinforcing mesh a393 factory

A393 reinforcing mesh is versatile and used in a myriad of construction applications. It is predominantly employed in the construction of heavy-duty slabs, such as those found in warehouses, factories, and commercial buildings. Additionally, this mesh is ideal for applications in road construction, bridges, and precast concrete products. Its use is also prevalent in residential projects, including underpinning and foundation walls, where enhanced strength is crucial. This mesh type is recognized for its ability to distribute loads evenly, thus reducing the risk of failure and extending the lifespan of concrete structures.

Advantages

The use of A393 reinforcing mesh offers several advantages. First, its robust construction significantly improves the tensile and compressive strength of concrete, making structures more resilient to external forces. Moreover, A393 mesh is designed to provide uniformity in stress distribution, which is pivotal in minimizing cracking and deformation over time. The mesh's effective weight-to-strength ratio also contributes to reduced material costs while ensuring structural safety.

Additionally, the manufacturing quality of A393 reinforcing mesh complies with strict industry standards, assuring builders of its performance and reliability. The ease of installation further enhances its appeal; contractors appreciate how the mesh can be laid quickly and efficiently, speeding up project timelines.

Conclusion

In conclusion, A393 reinforcing mesh plays a critical role in modern construction practices. Its unique features, coupled with a rigorous manufacturing process, make it an excellent choice for a variety of applications. Builders and contractors can rely on A393 mesh to enhance the durability and structural integrity of their projects. As the construction industry continues to evolve, the adoption of high-quality materials like A393 reinforcing mesh will undoubtedly contribute to safer, more resilient structures in the future.

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025